Complexity Made Simple

Posted 2025-12-30 06:35:39

0

333

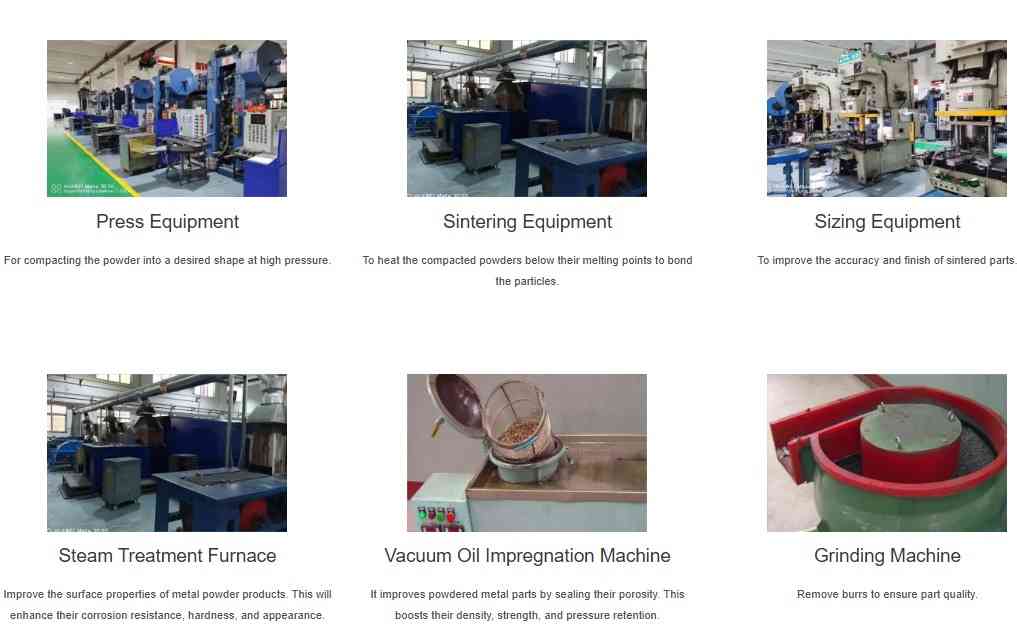

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Căutare

Categorii

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Citeste mai mult

Cleo County Noida Flat For Rent: Modern Living in a Premium Residential Community

Exploring the Cleo County Noida Flat For Rent options is a great way to ease your search for a...

Honkai: Star Rail 3.1 Guide - Janusopolis Sanctum

In the latest update of Honkai: Star Rail, version 3.1 introduces the Sanctum of Prophecy in...

Fit Cafe 700mg Review, Price, User Experience, Sale In USA

With the rise in obesity and weight-related health issues in the USA, many individuals are...

How to make customised IGNOU Project?

To make a customised IGNOU Project, you need to align strictly with IGNOU guidelines while...

Blood Cancer Market Industry Statistics: Growth, Share, Value, and Trends By 2032

"Executive Summary Blood Cancer Market Value, Size, Share and Projections

Global blood...