Complexity Made Simple

Posted 2025-12-30 06:35:39

0

344

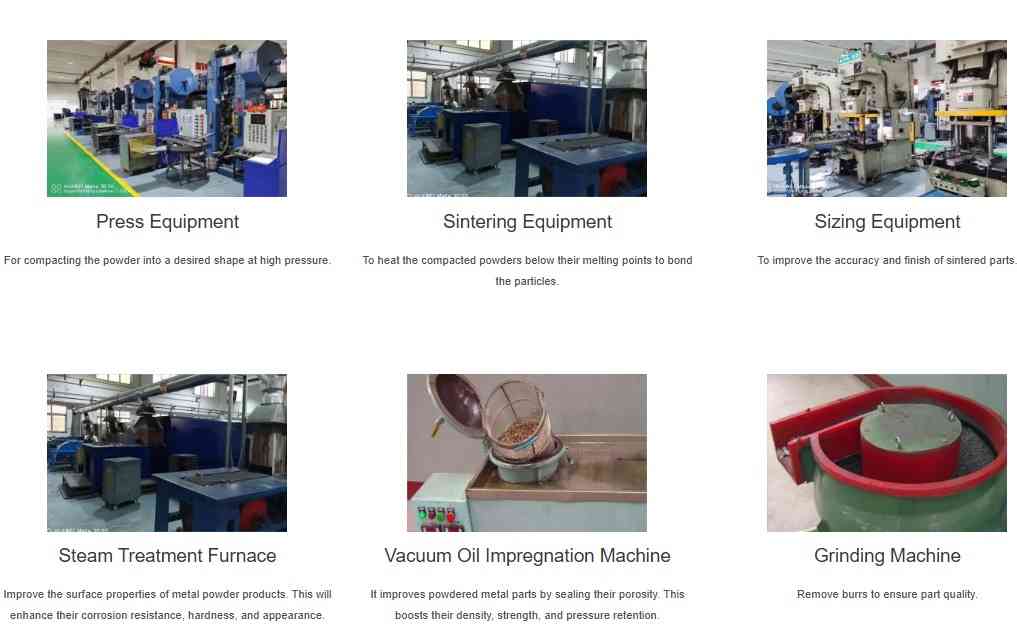

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Cerca

Categorie

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leggi tutto

Drug Safety Solutions and Pharmacovigilance Market Challenges: Growth, Share, Value, Size, and Scope By 2032

Global Demand Outlook for Executive Summary Drug Safety Solutions and Pharmacovigilance...

Is Hemp X CBD tested by third-party labs?

Pain is one of the most common health concerns affecting millions of people across the...

Self-Adhesive Labels Market: Trends, Growth Drivers, and Future Outlook (2025–2030)

Self-Adhesive Labels Market Overview

The Global Self-Adhesive Labels Market size is...

Mancode Male Enhancement Gummies Canada – Men Need It For Great Sexual Improvment?

Mancode Male Enhancement Gummies Canada🎕┈┈┈┈🎕❂⋯ Shop...

Global Opioid Market to Reach USD 28.45 Billion by 2034, Driven by Demand for Pain Management and Chronic Care Solutions

Market Overview

The global opioid market has demonstrated steady growth, with its...