Complexity Made Simple

Δημοσιευμένα 2025-12-30 06:35:39

0

336

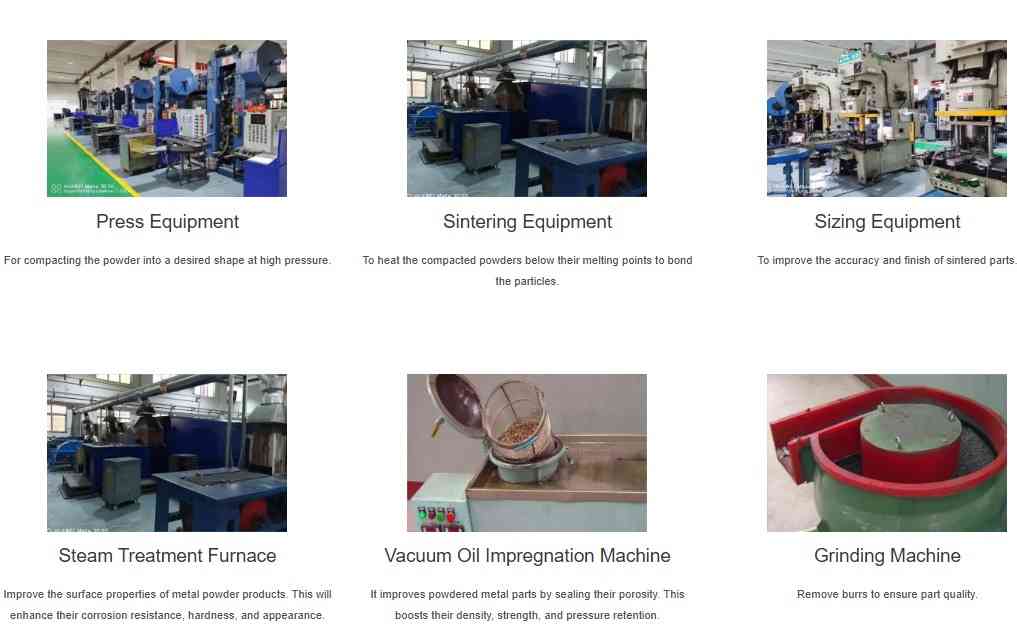

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Αναζήτηση

Κατηγορίες

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Διαβάζω περισσότερα

Para911 Parasites Cleanse Drops CA: No-1 Supplement Helpful For Parasites Health

Para 911 Canada With the rise of obesity and weight-related health issues in the UK, a growing...

How Agencies Build Content That Feels Human and Converts

Let’s be honest—most content online feels like it was churned out by a robot....

Reliable Fiber Internet & Leased Line for Marathahalli Businesses

Marathahalli is one of Bengaluru’s most active commercial and IT hotspots, home to tech...

How Bluefirecans Advances Personal Care with Two-Piece Aerosol Cans

The personal care sector continually adapts to consumer preferences for convenience, durability,...

Vans Harry Potter Shoes – House Styles & Details Unveiled

The wizarding world collides with streetwear as House pride gets a footwear upgrade.

Vans...