Complexity Made Simple

Postado 2025-12-30 06:35:39

0

324

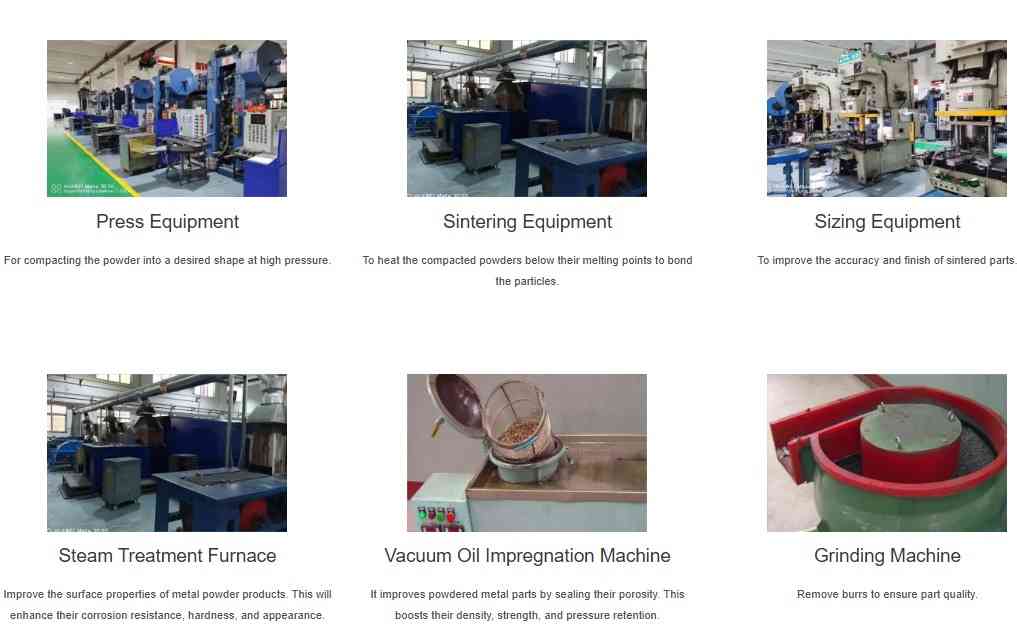

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia Mais

u4gm Black Ops 7 Analysis How to Use Combat Data to Sharpen Your Playstyle

Every player has a unique combat fingerprint, and Black Ops 7’s Combat Record system...

Digital Therapeutics Market Segmentation by Application, End-User, and Region

The global Digital Therapeutics (DTx) Market is entering a phase of rapid growth driven...

How to Stay Safe Playing Online Slots

Online slots are most of the maximum popular casino video games, captivating tens of millions of...

Types of Portfolio Management: Meaning, Objectives & Examples

Types of Portfolio Management: A Complete Guide for Every Investor

Managing money can feel...

AUTOMUGFACTORY Auto Mug Quality and Innovation

For modern commuters and travelers, the Auto Mug represents more than a simple beverage...