Complexity Made Simple

Posted 2025-12-30 06:35:39

0

343

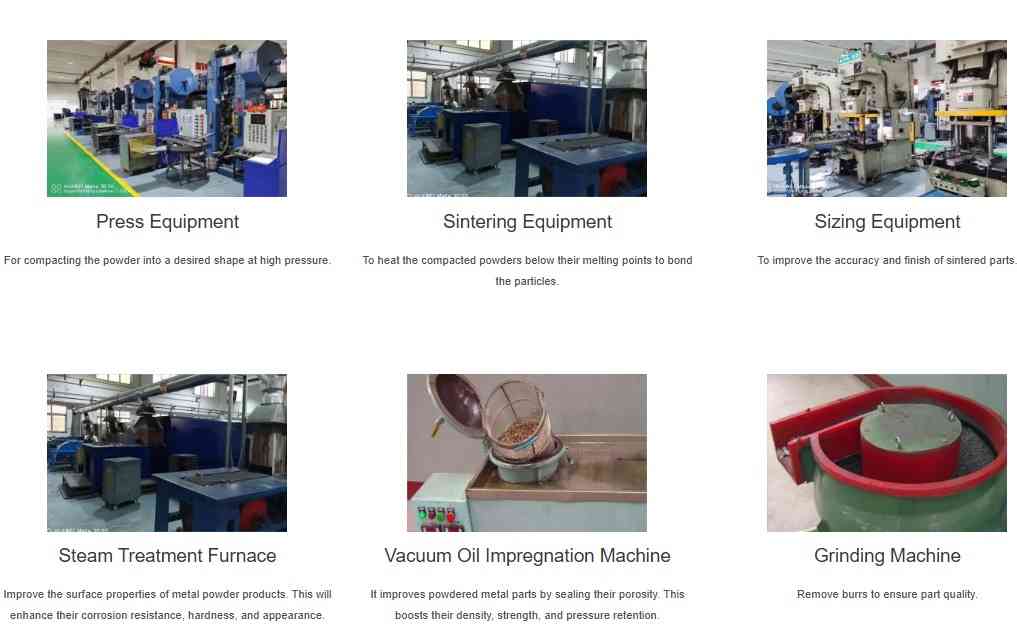

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Zoeken

Categorieën

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Alrafahiamed - Al Rafahia Med

🌿 Foundations of General Health and Well-Being

alrafahiamed General health is the harmonious...

Intel AI Marketing Workforce Moves to Streamline Processes

Intel is transforming its marketing operations by combining artificial intelligence with a...

https://www.facebook.com/groups/natureseasecbdgummiesreviews2026/

Natures Ease CBD Gummies fit easily into a busy lifestyle and can be taken anytime as part of a...

Seasonal Highlights to Enjoy on Kamakura Tours Year-Round

Kamakura, a coastal city steeped in history and culture, offers a rich tapestry of seasonal...

Europe Lithium-Ion Battery Market Size, Share, Trends, Key Players, Growth and Forecast 2025-2033

Europe Lithium-Ion Battery Market Overview

Market Size in 2024: USD 13.6 Billion

Market...