Complexity Made Simple

Posted 2025-12-30 06:35:39

0

327

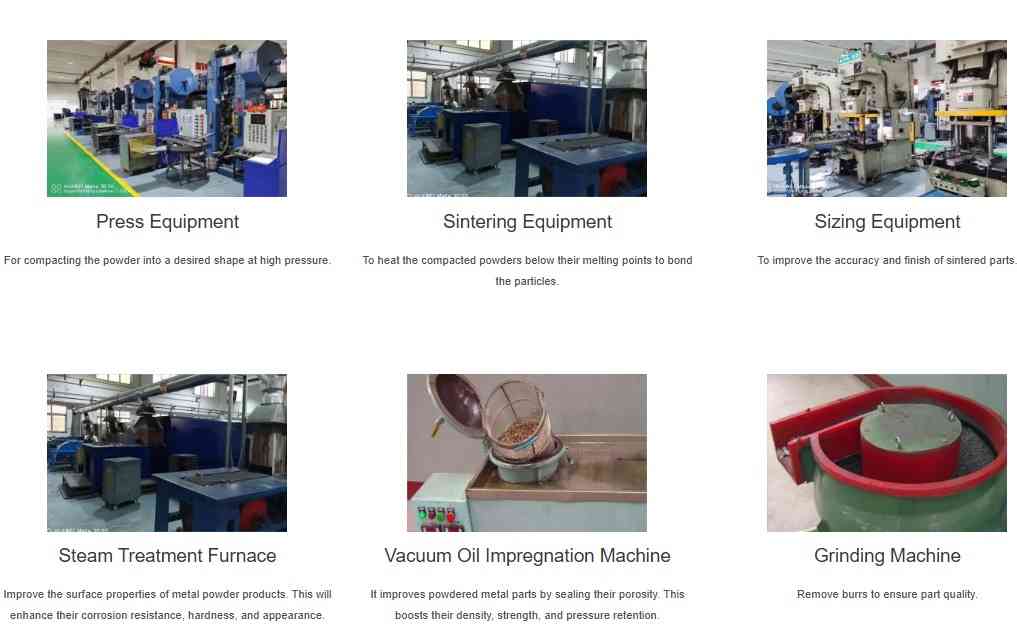

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Buscar

Categorías

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Unlocking the Value of Your Property: The Essential Role of a Commercial Real Estate Appraiser

In the dynamic world of real estate, understanding the true value of a property is paramount....

https://www.facebook.com/HumeHealthBodyPodOfficial/

ORDER NOW : https://healthyifyshop.com/OrderHumeHealthBodyPod

Hume Health...

How Carefor9 Supports First-Time Parents

Becoming a parent for the first time is one of life’s most beautiful experiences —...

In-Vitro Fertilization Services Market Revenue Analysis: Growth, Share, Value, Size, and Insights

"Executive Summary In-Vitro Fertilization Services Market Research: Share and Size...

What is the skin type best suited for Elorexa?

Elorexa was developed to tackle these common issues — not just to cover them up but to...