Complexity Made Simple

Posté 2025-12-30 06:35:39

0

341

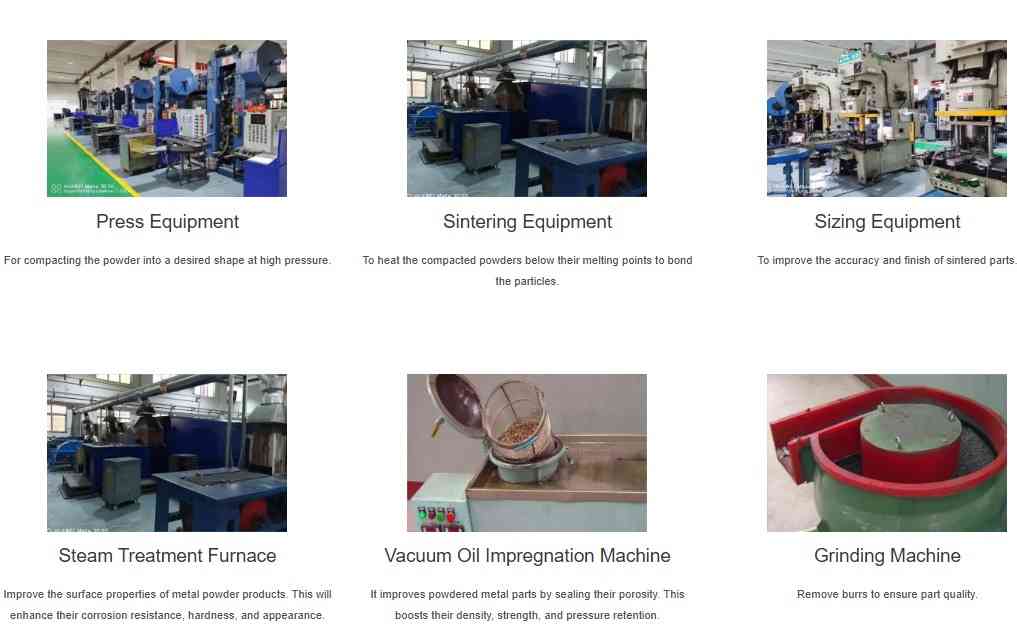

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Rechercher

Catégories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Lire la suite

https://www.facebook.com/Brain.Plus.Canada.Official/

Brain Plus Canada:- And extra importantly, is it truly as right as it claims to be? This article...

BIS FMCS: License for Foreign Manufacturer & Cost Guide

Introduction

India is a highly regulated market when it comes to product quality and safety. To...

Capital One Anti-Phishing Strategy: User Concerns

Concerns Arise Over Capital One's Anti-Phishing Communication Strategy

Credit card giant Capital...

Harmony Wave Gummies Review - It's Not Magic, It's Science!

A strong presence requires both psychological and physical well-being. A variety of CBD products...

Japan Box Office: Lord of the Rings, Monsters Inc. Surge

This past weekend, Japan emerged as a major box office force, witnessing significant openings for...