Complexity Made Simple

Posted 2025-12-30 06:35:39

0

346

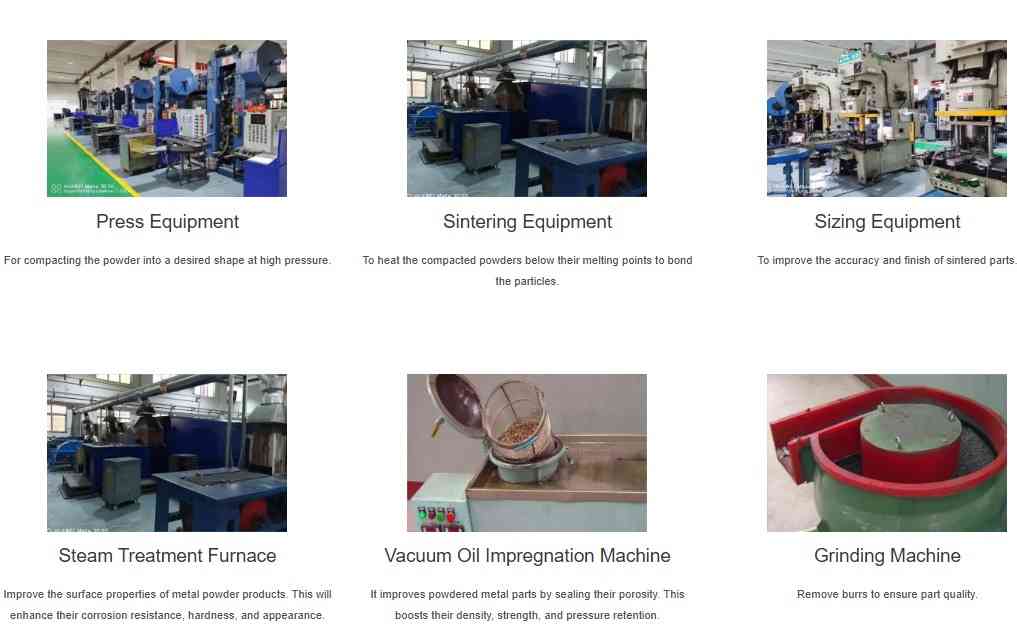

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Is Ozalyn suitable for both men and women?

Ozalyn is a weight loss supplement formulated to support individuals who are looking for a...

Tally Cloud Software in Delhi: The Smart Accounting Solution for Modern Businesses

In today’s fast-paced digital world, businesses in Delhi are rapidly moving towards...

Urine Creatinine Test: Assessing Kidney Health and Function

What Is the Urine Creatinine Test?

This test measures the concentration of creatinine in...

MMOWOW — The New Standard for BIGO Recharge

In the digital age where live streaming platforms like BIGO LIVE have become integral to global...

Box Office Slump: Narnia & The Tourist Disappoint

No studio exec I spoke with blamed weekend weather for the box office slump, and if anyone was...