Complexity Made Simple

Posted 2025-12-30 06:35:39

0

322

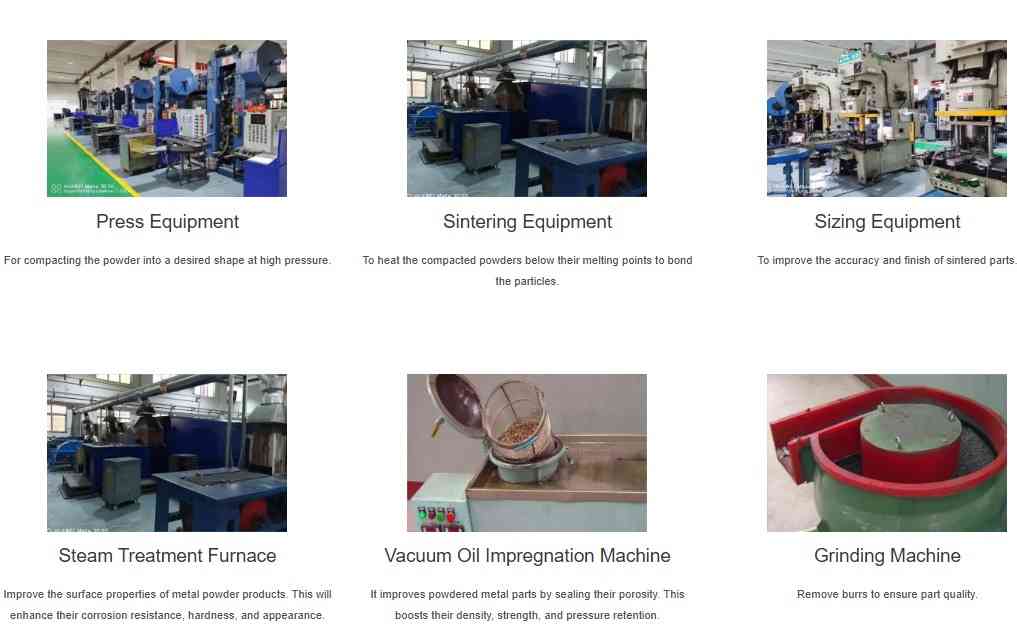

When a component's design includes complex features like thin walls, internal channels, or unique gear tooth profiles, conventional manufacturing can be costly and limiting. This is where the strengths of MIM Parts and powdered metal gears truly shine. Metal Injection Molding allows for the creation of elaborate, three-dimensional shapes that would be impossible or prohibitively expensive to machine. Similarly, the powdered metallurgy process for gears can consistently produce sophisticated splines and profiles in a single press operation. By choosing these advanced powder-based technologies, engineers can specify the exact geometry needed for optimal function without being constrained by traditional manufacturing hurdles.

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Buy Multivitamin And Multimineral Tablets Online | Nutrabuff | Get 25% OFF

If you want to boost your immunity, improve daily energy, and support overall health, Nutrabuff...

VPN Demand in Iran Surges – Risks and Warnings

Iranians have been scrambling for ways to access the internet since restrictions were tightened...

Anxiety Therapy vs Medication: Which Treatment Is Right for You?

When anxiety begins to interfere with daily life, choosing the right treatment can feel...

What Role Does Magnetic Powder Brake Play Today?

In many industrial control scenarios, the Magnetic Powder Brake serves as a subtle yet effective...

Hotel Irada | Exclusive 66-Acre Wine Estate Stay Near Pune

Hotel Irada | Exclusive 66-Acre Wine Estate Stay Near Pune

If you’ve ever dreamed of...