PC Hollow Sheets: The Modern Marvel in Construction and Design

The use of polycarbonate hollow sheets has become a standard in the field of modern architecture and construction as the search for materials that boast durability, are light, and add to the beauty of the building. These are hollow sheets made of polycarbonate that are structured in a way that the hollow chambers inside them drastically reduce the weight while still keeping incredible strength. Due to their groundbreaking design, they are widely used as skylights, greenhouses, decorative partitions, and safety barriers, etc. When comparing PC hollow sheets with PP hollow ones, it can be seen that the former possess higher impact resistance, have better optical clarity and are more weather-resistant. Consequently, PC hollow sheets are the first preference for long-life and high-performance projects. Knowing the inherent characteristics of the PC hollow sheet will allow the experts to make the right choice of the material that perfectly matches the requirements of the project.

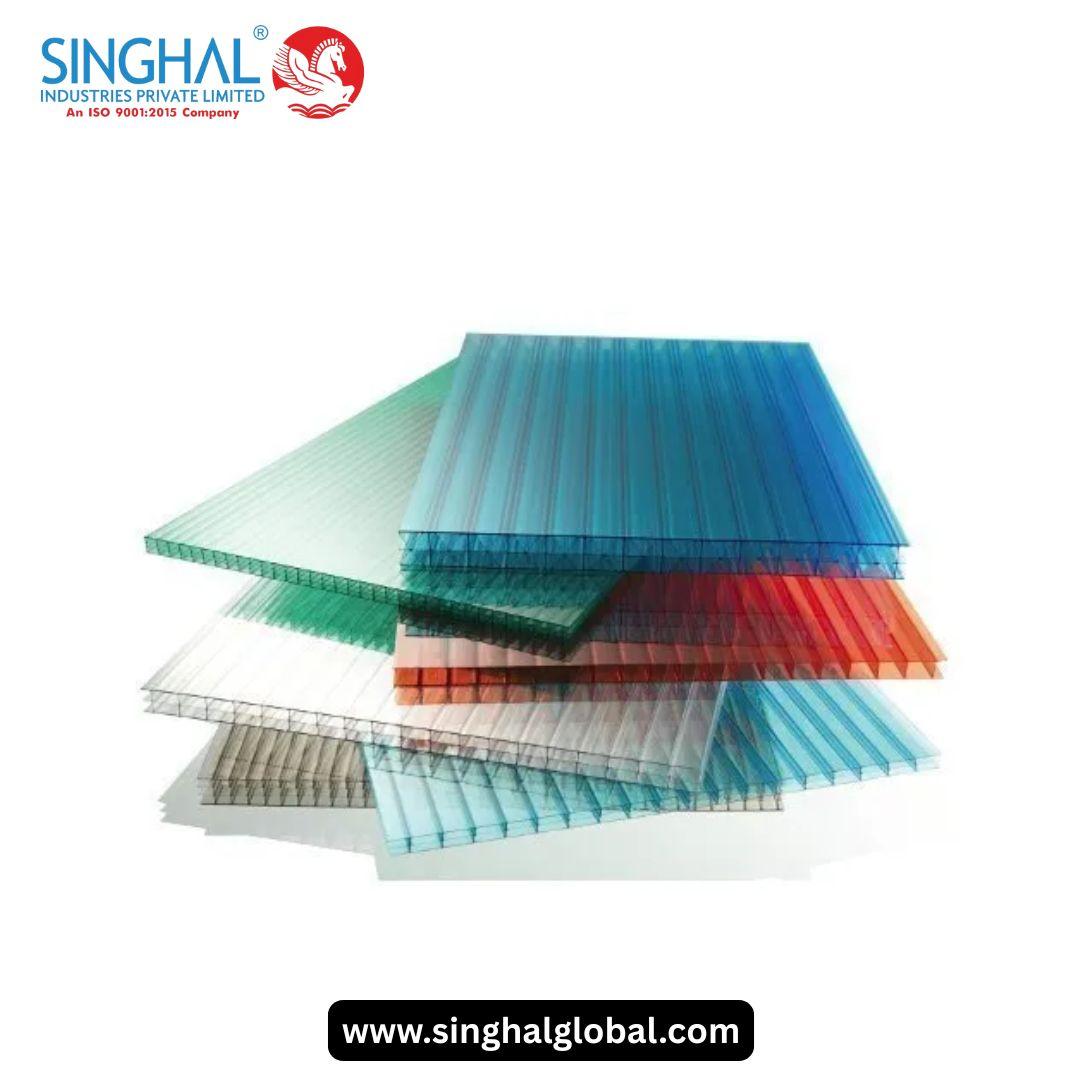

What Are PC Hollow Sheets and How Are They Manufactured?

The PC hollow sheet is a large-sized transparent panel made from polycarbonate, a thermoplastic that is recognized as the most optically clear and tough of all. These sheets have internal chambers—multiple hollow sections—that extend either parallel or perpendicular across the sheet, thus making them lightweight but strong ones. Generally, the process to make these sheets is extrusion where the raw polycarbonate resin is heated, and then it is forced through a mold to produce sheets with the internal dividers. After the initial cooling, thermoforming can also be used to shape the products. The hollow chambers, in which the sheets are made, have multiple uses like they lessen the total weight of the product, improve thermal insulation and increase the resistance to the impact. Manufacturing procedure makes sure that pc hollow sheets are not only functional but also flaunt their aesthetically sleek designs, thus they become suitable for both structural and decorative purposes.

Advantages of Using PC Hollow Sheets in Modern Construction

The advantages of the uses of the pc hollow sheet are the main reason for its popularity. One of the biggest advantages is its impact resistance as well; the polycarbonate is the most exteme case of being tougher than glass as well as other plastics, and thus it gives a high degree of safety in areas where the risk of vandalism or accidents is high. Due to their nature as very thin and light sheets, transportation and installation become more simple which in turn leads to lower labor and logistical costs. Moreover, these sheets are very good in repelling UV rays because of the special coating that they have and they never get yellow or degrade over time even if they have been exposed to direct sunlight for a long time. Through the hollow chambers, the product can now offer good thermal insulation as the air is trapped and helps control the room temperature. This is an attribute that can significantly lower energy use. Besides, their maximum transmission of light is one that natural illumination is provided, thus bright and inviting spaces are created and the need for artificial lighting is lessened. This combination of long life, energy efficiency, and optical clarity has made the PC hollow sheet the champion in various fields of application.

Comparing PC Hollow Sheets with PP Hollow Sheets

While both pc hollow sheet and pp hollow sheet are hollow thermoplastics, their differences at the core have an impact on the matter of how they are used in different fields. PP hollow sheets made of polypropylene are usually more flexible, lighter, and less expensive, which is why they are perfect for temporary applications like signage, packaging, or low-impact partitions. Nevertheless, lower impact resistance is their tendency along with faster degradation when exposed to UV rays for an extended period of time, thus their outdoor lifespan is limited. On the other hand, pc hollow sheets are stronger in terms of impact resistance, can resist UV rays, and are optically clear. Such are the characteristics that make them more appropriate for long-term outdoor usage, which include roofing, skylights, and safety barriers, where protection against weathering is necessary. The criteria between these two are project requirements—if the aspects of longevity and impact resistance are given priority, PC hollow sheets will be the best option available.

Versatile Applications of PC Hollow Sheets

The flexibility of PP hollow sheet can be seen in the application area that is very wide. Through the use of their artistic but still functional transparent roofing, skylight, and decorative facade, the architects and designers get the satisfaction of their customers as well as the awe of their competitors. Greenhouses are also taking advantage of the high light transmission and thermal insulation of pc hollow sheets and creating the ideal conditions for plant growth and at the same time lowering the heating costs. Inside the house, interior designers are creating partitions, wall claddings, and display cases that are both stylish and durable with the help of these sheets. Likewise, pc hollow sheets find their place in different fields of safety such as protective barriers, noise control walls, and vandal-resistant windows, because they are impact resistant. The fact that they can be there to resist deeply unfavorable environmental situations for years, in turn, ensures their indestructibility and makes them the best material for sustainable, long-lasting structural works.

Environmental Impact and Sustainability of PC Hollow Sheets

The issue of sustainability is gradually becoming an indispensable part of modern architecture and therefore, the ecologically conscious choice of materials such as pc hollow sheet is gaining ground. Polycarbonate is easily recyclable, and many of the manufacturers make content with already recycled material to lessen the environmental impact of their sheets. The lifetime of these sheets is very long - more than 20 years at times - which results in much less replacement and consequently lower amounts of waste. Besides, the thermal insulation aspects of the pc hollow sheets have a positive effect on energy conservation in buildings and therefore the carbon footprint of the latter gets reduced too. When the end of their life comes, proper disposal and recycling make their sustainability profile even better.

Conclusion

To sum up, PC hollow sheet are the most innovative materials that bring to light the fascinating features of strength, clearness, and lightness. Besides that, their use covers a variety of aspects - from architectural features and greenhouses to safety barriers, which means that these materials are versatile and beneficial in the field of modern construction. In terms of performance, as compared with pp hollow sheets, these materials lead in impact resistance and UV stability and are therefore more aesthetically clear and are considered the most suitable materials for long-term, high-performance projects. Moreover, as the factors of environmental protection and energy efficiency are gradually becoming the principal influences in this field, the recyclable character and the thermal insulation properties of PC hollow sheets will be instrumental to their presence in future developments. Collaboration with this avant-garde product not only guarantees structures are robust but also environmentally responsible and visually appealing.

Frequently Asked Questions

-

What are the main differences between PC hollow sheets and solid polycarbonate sheets?

PC hollow sheets are lighter and thermally insulating, and their installation takes less time. As for solid sheets, they have the highest impact resistance and privacy. -

Are PC hollow sheets UV resistant?

Yes, the majority of pc hollow sheets are endowed with UV inhibitors, thus they can keep their color and avoid separation due to exposure to sunlight. -

Can PC hollow sheets be used outdoors?

Without a doubt. They are the ones that can be applied outdoors in the areas of roofing, skylights, and protective barriers, as they possess the properties of weather resistance. -

How do I cut or shape PC hollow sheets?

The recommended tools are fine-tooth saws or precision lasers. Make sure the material is well-supported and be gentle while handling it in order to prevent cracks or scratches. -

Are PC hollow sheets recyclable?

Indeed, polycarbonate is recyclable, and there are several suppliers who offer sheets with recycled content. -

Who is the largest supplier of PC Hollow Sheets?

Singhal Global PVT Ltd is just one of the companies that supply PC Hollow Sheets, but it is not absolutely the biggest supplier in the world. -

Who is the largest exporter of PC Hollow Sheets?

Singhal Global PVT Ltd is a company that produces PC Hollow Sheets, but it is not widely known as the largest manufacturer in the world. -

Who is the largest manufacturers of PC Hollow Sheets?

Singhal Global PVT Ltd is one of the manufacturers of PC Hollow Sheets, but it is not generally recognized as the largest manufacturer worldwide. -

What is the cost difference between PC and PP hollow sheets?

Although the first cost of PC sheets is more expensive, their durability and long lifespan make them more cost-effective after a certain period. -

Where can I buy high-quality PC hollow sheets?

Trusted plastic suppliers, industrial distributors, and online platforms that are specialized in the building materials sector are some of the most dependable sources.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness