What Are Brazed Plate Heat Exchangers and How Do They Work?

In the world of thermal operation, effectiveness and conciseness frequently determine which technology prevails in specific operations. Brazed plate heat exchangers have surfaced as one of the most popular results for operations taking effective heat transfer in a minimum footmark. These innovative bias represent a significant advancement over traditional shell- and- tube designs, offering superior performance characteristics that make them ideal for refrigeration, HVAC systems, artificial processes, and multitudinous other operations. Understanding how brazed plate heat exchangers serve and what sets them piecemeal from other heat exchange technologies helps masterminds and installation directors elect the optimal outfit for their thermal operation requirements.

Construction and Design Principles

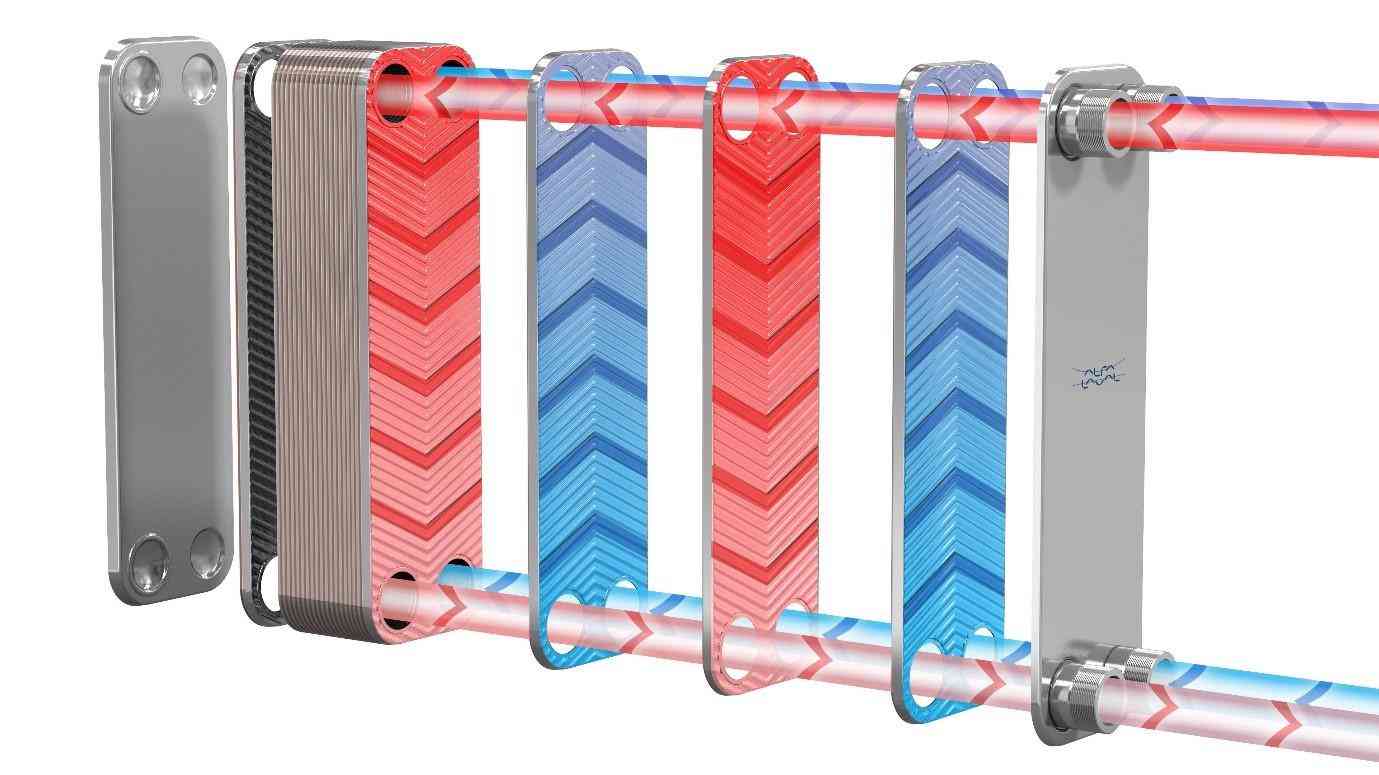

Brazed plate heat exchangers correspond of a series of thin, corrugated pristine sword plates piled together and brazed using bobby or nickel as the cling material. The brazing process creates a endless, vacuum-tight seal between the plates, barring the need for gaskets, bolts, or frame structures needed in other plate heat exchanger designs. Each plate features a specific corrugation pattern that creates turbulence in the fluid inflow, significantly enhancing heat transfer effectiveness.

The corrugations on conterminous plates communicate each other at multiple points, creating a rigid structure able of opposing substantial pressure differentials. The spaces between plates form channels through which hot and cold fluids flow in interspersing patterns. Thiscounter-flow orcross-flow arrangement maximizes the temperature grade between fluids, optimizing heat transfer effectiveness. The entire assembly is generally compact, featherlight, and remarkably effective compared to its size.

How Heat Transfer Occurs

The functional principle behind brazed plate heat exchangers is elegantly simple yet largely effective. Two fluids at different temperatures enter the heat exchanger through separate anchorages. The hot fluid flows through one set of channels while the cold fluid flows through conterminous channels in the contrary direction. Heat transfers from the hot fluid through the thin pristine sword plates to the cold fluid.

The corrugated pattern of the plates serves multiple critical functions. First, it creates turbulence in the fluid inflow, dismembering the boundary subcaste that generally forms along smooth shells. This turbulence dramatically increases the heat transfer measure, allowing more effective thermal energy exchange. Second, the corrugations increase the effective face area available for heat transfer without adding the overall footmark of the unit. Third, the contact points between plates give structural support, enabling the assembly to repel high pressures despite the thin plate construction.

The brazing material — generally bobby

for standard operations or nickel for high- temperature or sharp surroundings — creates a metallurgical bond that ensures excellent thermal conductivity and leak- evidence operation. This endless seal means brazed plate heat exchangers can operate at advanced pressures and temperatures than gasketed druthers while maintaining complete separation between the two fluid aqueducts.

Crucial Advantages Over Indispensable Designs

Brazed plate heat exchangers offer several compelling advantages that explain their wide relinquishment across different diligence. Their compact size delivers exceptional heat transfer capacity in a bit of the space needed by shell- and- tube heat exchangers. This space effectiveness proves inestimable in operations where installation area is limited or precious.

The high turbulence created by plate corrugations results in superior heat transfer portions, frequently three to five times advanced than shell- and- tube designs. This effectiveness translates to lower outfit sizes, reduced material costs, and lower energy consumption. Thecounter-flow design allows approach temperatures as close as one degree, enabling maximum thermal effectiveness.

continuity represents another significant advantage. The brazed construction eliminates gaskets that can degrade, leak, or bear periodic relief. This makes brazed units nearly conservation-free and suitable for operations where trustability is critical. The absence of gaskets also allows operation at advanced temperatures and pressures than gasketed plate heat exchangers can handle.

Common operations and diligence

The versatility of brazed plate heat exchangers makes them suitable for an emotional range of operations. In refrigeration systems, they serve as evaporators, condensers, and prodigals, offering compact results that maximize cooling effectiveness. HVAC systems use them for heating and cooling water circuits, domestic hot water product, and energy recovery operations.

Artificial process operations include heat recovery, oil painting cooling, chemical processing, and food and libation product. The pharmaceutical assiduity values their easy- to-clean shells and capability to maintain strict hygiene norms. District heating and cooling systems profit from their compact size and high effectiveness when transferring heat between primary and secondary circuits.

Their capability to handle both liquid- to- liquid and two- phase heat transfer makes them adaptable to different thermal operation challenges. From small domestic heating systems to large artificial processes, brazed plate technology scales effectively across a wide power range.

Limitations and Considerations

While brazed plate heat exchangers exceed in numerous operations, they do have limitations that masterminds must consider. The endless brazed construction means they can not be disassembled for mechanical cleaning, making them infelicitous for fluids with high fouling eventuality or particulate content. operations involving dirty fluids, slurries, or liquids prone to crystallization may bear indispensable heat exchanger designs or upstream filtration.

The thin plates and narrow channels also make these units sensitive to pressure surges and water hammer, taking proper system design to help damage. also, while bobby brazing suits most operations, fluids inharmonious with bobby necessitate more precious nickel- brazed druthers.

Partnering with Endured Manufacturers

Opting for the right heat exchanger technology and ensuring proper system integration requires moxie and experience. Working with established thermal operation specialists ensures you admit outfit designed for optimal performance in your specific operation. Companies like Kinetic Engineering bring decades of experience in designing and manufacturing heat exchange results for different artificial conditions. Their comprehensive understanding of thermal dynamics and operation-specific challenges helps guests achieve maximum effectiveness and trustability.

Conclusion

Brazed plate heat exchangers represent a sophisticated result to thermal operation challenges, combining compact design, exceptional effectiveness, and dependable operation in a conservation-free package. Their unique construction system creates robust, high- performance units suitable for innumerous operations across domestic, marketable, and artificial sectors. While they may not suit every operation, their advantages in size, effectiveness, and continuity make them the favored choice for numerous ultramodern thermal operation systems. Understanding their operating principles and operation parameters enables informed opinions that optimize both performance and cost- effectiveness in heat exchange operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness