Electric Resistance Welding: Principles, Applications, and Best Practices

Electric resistance welding (ERW) has become a cornerstone technology in modern manufacturing, enabling precise, high-speed, and cost-effective joining of metals across industries. From automotive assembly lines to heavy industrial fabrication, understanding the principles, applications, and best practices of ERW is crucial for manufacturing engineers, OEMs, and factory decision-makers looking to optimize productivity, quality, and reliability.

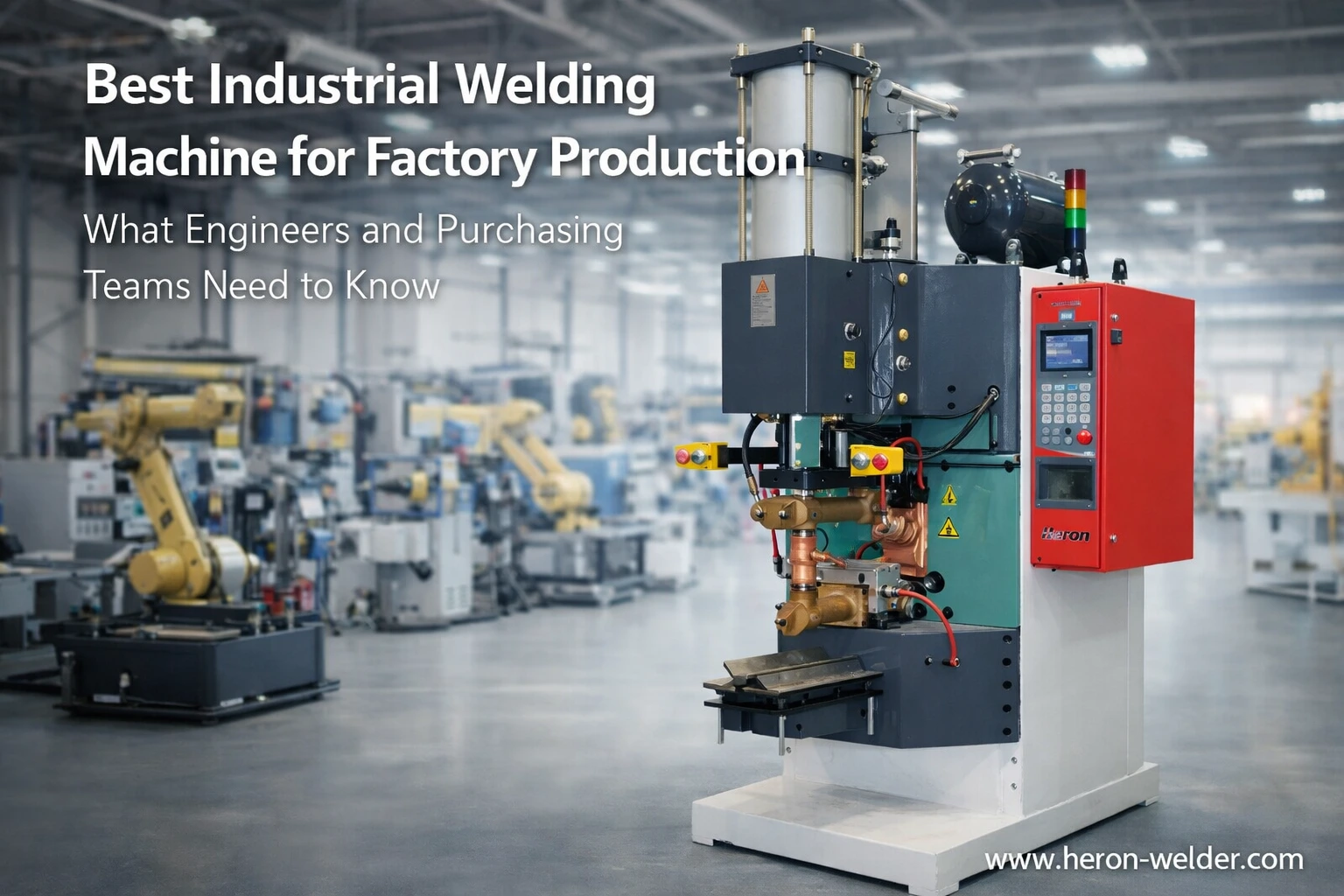

Heron Welder, a global leader in industrial welding and metal-joining equipment, provides advanced ERW solutions including spot, projection, seam, MFDC, and capacitor discharge welding machines tailored for automated and high-volume production environments.

What is Electric Resistance Welding?

Electric resistance welding is a process in which heat generated by electrical resistance is used to join two or more metal pieces. Unlike traditional welding methods that rely on an external heat source like a flame or arc, ERW uses the natural resistance of metals to electrical current to produce localized heat, allowing metals to fuse without melting the base material.

Key principles of ERW include:

-

Current Flow: An electric current passes through the metal workpieces.

-

Pressure Application: Electrodes or rollers apply pressure to the contact area, ensuring intimate metal contact.

-

Heat Generation: The resistance of the metal to the electrical current generates heat, which softens or fuses the metals.

-

Solid-State Joining: Upon cooling under pressure, a strong, metallurgical bond forms at the joint.

This combination of electricity and pressure enables highly repeatable, precise, and automated welding suitable for a wide range of materials and thicknesses.

Types of Electric Resistance Welding

ERW can be categorized into several methods, each suited for specific applications:

1. Spot Welding

Spot welding is one of the most common forms of ERW, widely used in the automotive and appliance industries. Two electrodes apply pressure and pass current through overlapping metal sheets, creating a localized weld spot. Spot welding is ideal for high-speed assembly lines, offering consistent quality with minimal operator intervention.

2. Projection Welding

In projection welding, current concentrates on raised portions (projections) of a workpiece, producing a weld at multiple points simultaneously. This method is commonly used for fasteners, studs, and complex assemblies where multiple joints are needed in a single cycle.

3. Seam Welding

Seam welding involves rolling electrodes that produce continuous welds along overlapping metal edges. Applications include fuel tanks, pipes, and tubing, where airtight or watertight joints are critical.

4. MFDC and Capacitor Discharge Welding

Medium-frequency direct current (MFDC) and capacitor discharge (CD) welding are advanced ERW methods designed for precision and speed. They are ideal for joining thin metals, dissimilar materials, and components that require minimal heat-affected zones, such as electronics, medical devices, and automotive connectors.

Applications Across Industries

ERW’s versatility makes it indispensable in multiple sectors:

-

Automotive Manufacturing: Body panels, chassis components, and battery enclosures.

-

Aerospace and Aviation: Lightweight structural assemblies and landing gear components.

-

Consumer Appliances: Refrigerators, washing machines, and HVAC units.

-

Industrial Fabrication: Steel pipes, tubes, and high-strength structural parts.

-

Electronics and Electrical Components: Switchgear, connectors, and terminal assemblies.

Heron Welder’s advanced ERW solutions are engineered to support these demanding applications, delivering high throughput, consistent weld quality, and seamless integration into automated production lines.

Advantages of Electric Resistance Welding

ERW offers several advantages over traditional welding methods:

-

Speed and Efficiency: High-speed cycles enable mass production without compromising quality.

-

Energy Efficiency: ERW uses localized heat, reducing overall energy consumption.

-

Automation-Friendly: Easily integrates with robotic and automated systems.

-

Consistent Quality: Precise control of current, pressure, and timing ensures repeatable welds.

-

Minimal Distortion: Low heat input reduces warping and preserves part geometry.

By implementing Heron’s ERW systems, manufacturers can optimize throughput while maintaining stringent quality standards.

Best Practices for ERW

To maximize performance and longevity in ERW applications, consider these best practices:

-

Proper Electrode Maintenance: Regularly inspect and dress electrodes to prevent overheating and inconsistent welds.

-

Correct Parameter Settings: Optimize current, pressure, and welding time based on material type and thickness.

-

Material Preparation: Ensure clean, oxide-free surfaces for optimal electrical contact.

-

Integration with Automation: Utilize advanced controllers and sensors to monitor welding quality in real-time.

-

Routine Calibration: Periodically calibrate ERW equipment to maintain precise performance and prevent defects.

Why Choose Heron Welder for Electric Resistance Welding

Heron Welder provides a comprehensive range of ERW machines and systems designed for industrial-scale and precision applications. Benefits include:

-

Tailored solutions for specific production requirements.

-

Integration-ready equipment compatible with robotic automation.

-

Experienced technical support for commissioning, training, and maintenance.

-

Global expertise in delivering reliable, long-lasting ERW solutions across industries.

FAQs About Electric Resistance Welding

Q1: What metals can be joined with ERW?

A1: ERW is effective for steel, stainless steel, aluminum, copper, and certain coated metals, depending on the welding method used.

Q2: How does ERW differ from arc welding?

A2: ERW uses electrical resistance and pressure to join metals without an external arc, resulting in faster, more precise, and energy-efficient welds.

Q3: Can ERW be automated?

A3: Yes. ERW is highly compatible with robotic and automated production lines, ideal for high-volume manufacturing.

Q4: What industries benefit most from ERW?

A4: Automotive, aerospace, industrial fabrication, consumer appliances, electronics, and electrical manufacturing industries rely heavily on ERW.

Q5: How does Heron ensure consistent weld quality?

A5: Heron’s machines use advanced controllers, precise parameter settings, and robust electrode designs to deliver repeatable, high-quality welds.

Conclusion

Electric resistance welding continues to revolutionize industrial manufacturing by offering speed, precision, and energy efficiency. Selecting the right ERW system is critical for achieving optimal production outcomes and long-term reliability.

Heron Welder combines decades of expertise, advanced technology, and global support to provide customized ERW solutions for OEMs, engineers, and automation integrators.

Ready to optimize your production line with advanced electric resistance welding? Contact Heron today to request a quote or consult with our experts for tailored welding and automation solutions.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness