How FPC Flat Connector Guarantees Reliable Performance

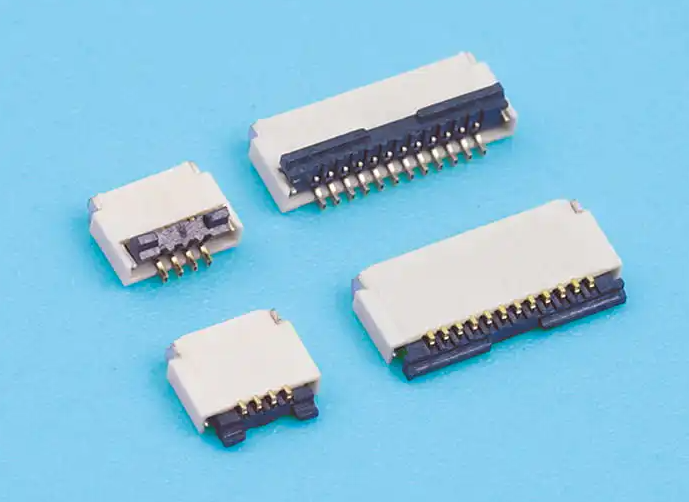

Introduction to FPC Flat Connectors

A FPC Flat Connector is widely used in electronic devices where space constraints and flexibility are critical, such as smartphones, laptops, cameras, and wearable devices. One of the most important performance characteristics of these connectors is their ability to maintain low contact resistance while ensuring stable signal transmission. High contact resistance or signal fluctuation can result in data errors, intermittent connections, and device malfunctions. Therefore, manufacturers and designers take several measures to guarantee both contact integrity and signal stability throughout the product’s lifespan.

Material Selection and Contact Design

The choice of materials for the connector contacts is critical to achieving low resistance and stable signals. Gold plating is commonly applied to the contact surfaces due to its excellent conductivity and corrosion resistance. This minimizes oxidation and wear that can otherwise increase contact resistance over time. Copper alloys are typically used for the base material, providing both mechanical strength and reliable electrical conductivity. The geometry of the contacts, including contact width, thickness, and spring tension, is also carefully designed to maximize surface area engagement with the FPC pads, reducing the risk of intermittent connections.

Maintaining Mechanical Reliability

Mechanical stability plays a significant role in contact performance. FPC connectors are often subjected to vibrations, thermal expansion, and repeated insertion and removal cycles. To maintain consistent contact pressure, manufacturers incorporate precise spring mechanisms or reinforced contact designs. This ensures that the connection remains firm under varying environmental conditions, preventing gaps that could increase contact resistance or degrade signal quality. Proper insertion depth and alignment during assembly are equally important to maintain consistent contact over time.

Surface Treatment and Coating

Surface treatment further enhances signal stability and reduces resistance. The application of anti-oxidation coatings, such as gold or nickel layers, protects the contact surfaces from corrosion and environmental degradation. These coatings also provide smoother surfaces for better electrical contact, reducing micro-arcing or intermittent connectivity. Some high-performance connectors feature multi-layer coatings designed to withstand high-frequency signals without introducing impedance inconsistencies, ensuring stable data transmission in sensitive electronic systems.

Design Considerations for Signal Integrity

Signal stability in FPC connectors is influenced not only by contact resistance but also by impedance matching and crosstalk reduction. The pitch of the contacts, spacing between lines, and connector layout are carefully engineered to minimize interference. For high-speed data applications, connectors are tested to meet strict signal integrity standards, ensuring low insertion loss and minimal reflection. These measures guarantee that even in compact designs or densely packed electronic devices, the connector can transmit data reliably without errors.

Testing and Quality Control

Reliable performance of FPC connectors is confirmed through rigorous testing procedures. Electrical testing measures contact resistance and signal continuity under various environmental stresses, including temperature cycles, humidity, vibration, and repeated mating cycles. Quality control at a reputable FPC Flat Connector manufacturer ensures that each connector meets stringent specifications, providing consistent performance in end-use applications.

Ensuring low contact resistance and stable signal transmission in a FPC Flat Connector involves a combination of high-quality materials, precise contact design, mechanical reliability, surface coatings, and careful layout for signal integrity. Through rigorous testing and quality control, these connectors maintain consistent electrical performance even in demanding applications. Proper design and material selection are essential for achieving long-term reliability, making FPC flat connectors a critical component in modern compact and high-performance electronic devices.

1、 CKT: 13Pin to 71Pin

2、 Current rating: 0.2A AC/DC

3、Voltage rating(max): 30V, AC/DC

4、Working Temperature: -25°C~+85°C, (Including temperature rise in applying electrical current)

5、Contact resistance:Initial value ≤40mΩ After environmental testing ≤60mΩ

6、Insulation resistance:≥50MQ

7、Withstand voltage:500VAC(rms)

8、Applicable PCB board thickness:1.6mm to 2.0mm

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness