Shipping Challenges for Durable Eyeshadow Pallets

The Role of Protective Packaging

Eyeshadow Pallets are delicate products that require careful handling during storage and transportation. To prevent damage, brands often incorporate shockproof and drop-resistant packaging. While this type of design protects the makeup inside, it also introduces considerations for shipping and logistics. Balancing protection with efficient handling is essential to ensure products arrive in perfect condition without adding unnecessary costs or complications.

Shockproof Design: Benefits and Considerations

Shockproof packaging uses cushioning materials, reinforced edges, and structural supports to absorb impacts. For Eyeshadow Pallets, these features reduce the risk of broken pans, cracked powders, and spilled pigments. From a consumer perspective, enhanced protection increases satisfaction and reduces return rates. However, the addition of padding or heavier materials can increase package dimensions and weight, potentially affecting shipping fees and storage efficiency.

Impact on Shipping Efficiency

While protective packaging enhances product safety, it can create challenges for logistics. Larger or irregularly shaped boxes may require more storage space in warehouses and trucks. Extra weight can increase shipping costs and may require adjustments in supply chain planning. Brands must carefully consider these factors, balancing the desire for maximum product protection with the need for cost-effective and streamlined distribution.

Sustainability and Material Selection

Many brands now face the dual challenge of protecting products while maintaining sustainability. Shockproof and drop-resistant packaging often uses plastics or thick foam, which can be less eco-friendly. Selecting biodegradable or recyclable materials can help reduce environmental impact while still providing adequate protection for Eyeshadow Pallets. Thoughtful material choice ensures that the packaging meets both logistical and environmental standards.

Optimizing Packaging for Logistics

To minimize logistical challenges, brands can optimize the internal layout and external design of Eyeshadow Pallets packaging. Modular inserts, compact cushioning, and stackable boxes allow efficient use of space without compromising safety. Testing packaging under real-world shipping conditions helps identify potential weaknesses and ensures that protective designs do not interfere with handling, storage, or delivery efficiency.

Protecting Products Without Hindering Logistics

Protective packaging for Eyeshadow Pallets is essential to maintain product quality and customer satisfaction. While shockproof and drop-resistant designs improve durability, they also require careful consideration of weight, dimensions, and material choice to avoid logistical challenges. By balancing protection, sustainability, and shipping efficiency, brands can deliver products safely and economically, ensuring that both aesthetics and practicality are preserved throughout the supply chain.

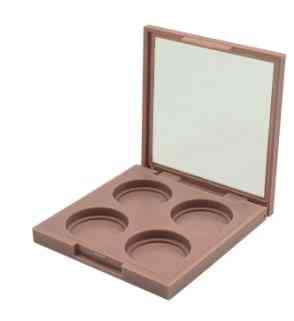

Classification: Eyeshadow palette-4 grids/ 6 grids/ multiple grids

External size:92.0*63.0*13.3mm

Net weight:43g

Material: ABS/PS/AS

Secondary process feasible: Electroplating / bronzing / screen printing / hot transferring / water transferring / 3D relief / matte plating

Color colors/ 6 colors/ multiple colors

Can install a mirror or not: Yes

Structure: Square. Composed of cap, base, and insert, with a square round round-corner buckle.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness