How Yd Enhances Polyphen Sandwich Panel Manufacturer Performance

Polyphen Sandwich Panel Manufacturer plays a pivotal role in modern industrial and cleanroom construction, and when yd-purification is mentioned, it represents high-quality panels that ensure structural strength, thermal insulation, and hygiene standards, which raises an important question: how do Sandwich Panel Manufacturer solutions transform industrial building efficiency and safety?

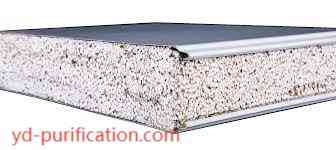

Industrial projects increasingly demand materials that offer strength, durability, and functional versatility.panels combine rigid outer layers with high-performance core materials, resulting in lightweight yet robust panels suitable for walls, ceilings, and partitions. Their modular design supports rapid installation and consistent performance across large facilities.

Thermal insulation is a key advantage. Proper insulation reduces energy consumption by maintaining stable indoor temperatures, which protects sensitive equipment and minimizes operational fluctuations. In addition, efficient panels contribute to environmental responsibility by reducing energy loss and optimizing resource usage.

Fire resistance and safety compliance are central considerations in industrial construction. Polyphen sandwich panels incorporate materials that resist ignition and slow the spread of flames. These characteristics improve worker safety, satisfy regulatory standards, and safeguard valuable machinery and inventory.

Acoustic performance is another critical factor. In facilities where machinery generates substantial noise, panels help absorb sound and reduce transmission between sections, improving workplace comfort and operational focus. This capability is particularly valuable in research and production zones where concentration is crucial.

Hygiene and contamination control remain essential in cleanroom applications. Smooth, non-porous surfaces are easy to clean and resist microbial growth, ensuring compliance with strict hygiene protocols. The panels'chemical-resistant coatings allow frequent cleaning without compromising material integrity.

Installation efficiency supports project timelines and reduces downtime. Panels are designed for simple assembly, with interlocking edges, precise alignment, and lightweight handling that allow workers to complete large installations with minimal effort. This speed improves workflow and reduces labor costs without sacrificing quality.

Durability over time is enhanced by corrosion-resistant surfaces, moisture protection, and high structural stability. These features ensure that the panels maintain their appearance, insulation, and safety characteristics throughout years of continuous operation, making them reliable long-term investments.

Design flexibility accommodates aesthetic and functional requirements. Panels are available in various colors, textures, and thicknesses, enabling architects and engineers to match design visions while maintaining structural and operational standards. This versatility makes the material suitable for industrial, commercial, and high-tech facilities.

Maintenance simplicity ensures panels remain effective without extensive intervention. Routine inspections, quick surface cleaning, and modular replacements prevent long-term degradation, allowing facilities to operate efficiently and meet regulatory obligations consistently.

Adopting advanced panel solutions demonstrates a commitment to efficiency, safety, and operational sustainability. Facilities using these materials can achieve optimal energy performance, structural reliability, and hygienic standards. For more detailed information on the advantages of these panels, Yd-purification provides comprehensive guidance at: https://www.yd-purification.com/news/industry-news/what-s-the-advantages-of-polyphen-sandwich-panel.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness