The Unseen Workhorses: How Advanced Materials Define Modern Powdered Metal Gears

When engineers specify powdered metal gears for a critical application, they are selecting far more than just a shape; they are choosing a material system engineered for performance. The evolution of metal powders and treatments has transformed these components from simple alternatives into high-performance solutions that often outperform their traditionally machined counterparts.

The core strength of modern powdered metal gears lies in sophisticated alloy systems. While early versions relied on basic iron-carbon mixes, today's materials include diffusion-alloyed steels, pre-alloyed nickel and molybdenum steels, and even stainless steel powders. These advanced materials, when compacted and sintered, provide a tailored microstructure that balances tensile strength, ductility, and wear resistance. For instance, a low-alloy steel powder might be selected for a high-strength, heat-treated gear in a transmission, while a copper-infiltrated iron powder could be chosen for a balance of strength and thermal conductivity.

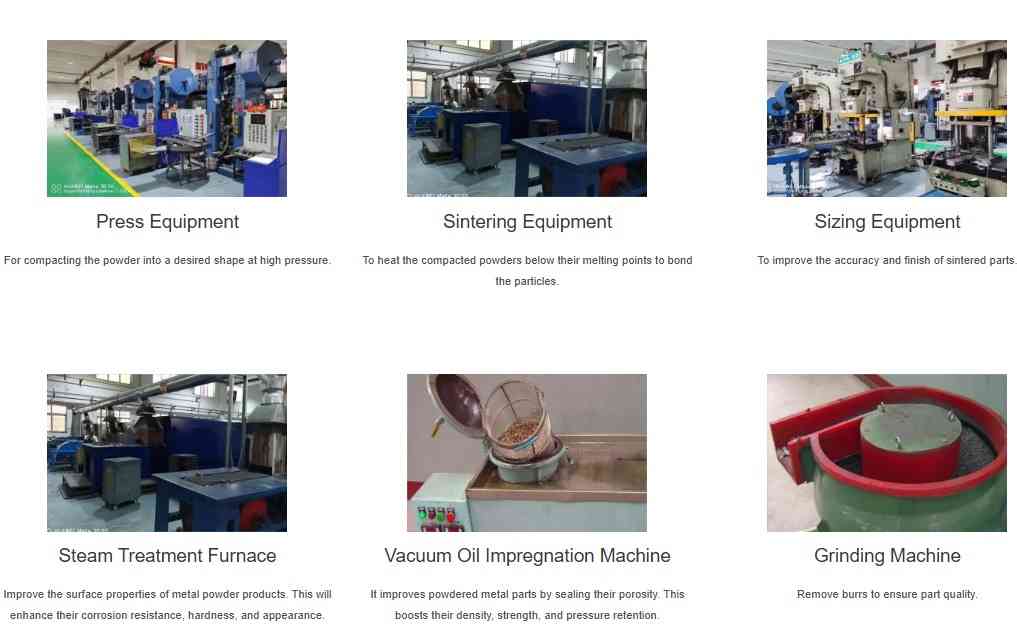

This material science directly enables one of the key advantages of powdered metal gears: their exceptional response to secondary treatments. The controlled porosity inherent in the sintered process is not a weakness but a design feature. It allows for deep and uniform case hardening during processes like carburizing. The interconnected pores enable carbon to diffuse evenly throughout the part, creating a gear with a hard, wear-resistant exterior and a tough, shock-absorbing core. Similarly, this porosity is leveraged for oil impregnation. Vacuum-impregnated lubricant stored within the gear's structure is released during operation, providing continuous internal lubrication that reduces friction, manages heat, and significantly extends service life—a feature impossible to replicate in a fully dense, wrought gear.

Furthermore, the material efficiency of the process contributes directly to the gear's performance profile. Because powdered metal gears are formed to a near-net shape, the grain flow of the metal is not cut through as it is in a machined gear. This uninterrupted grain structure, combined with the ability to press in optimized tooth root geometries with full radii, results in a component with superior fatigue resistance and durability. The precise control over density also allows engineers to fine-tune the gear's density for specific needs, such as creating slightly more porous powdered metal gears in applications where noise and vibration damping are priorities.

From the atomic composition of the starting powder to the final heat-treated surface, every aspect of a powdered metal gears and MIM Parts is a product of intentional material engineering. This holistic approach ensures that these components are not merely copies of machined parts, but are uniquely optimized designs that leverage the full potential of powder metallurgy to meet the demanding challenges of modern machinery.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness