Can Mold Customization Really Improve Your Factory Workflow?

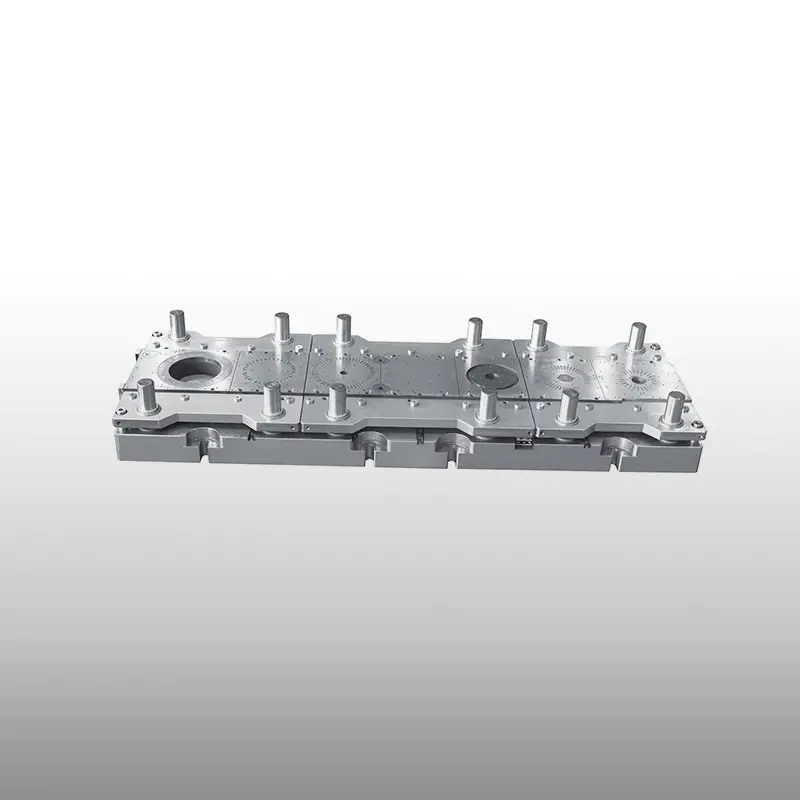

Customizing molds is becoming a key factor for manufacturers seeking precision, efficiency, and flexibility in production. Mold Customization allows factories to produce components that meet exact specifications, reduce waste, and adapt quickly to design changes. Working with professional Mold Customization Manufacturers can make a significant difference in achieving these goals.

Precision is one of the main benefits of Mold Customization. Every mold is designed to the exact requirements of the product, allowing manufacturers to produce parts with consistent quality and tight tolerances. This level of accuracy is crucial in industries such as automotive, electronics, and aerospace, where even minor deviations can impact assembly and performance. Experienced Mold Customization Manufacturers have the technical expertise and tools to deliver molds that maintain precision across high-volume production.

Flexibility is another advantage. By working with Mold Customization Manufacturers, companies can create molds tailored to unique product shapes, sizes, and materials. This customization reduces the need for multiple generic molds and simplifies the production process. Customized molds also allow factories to quickly adjust to new product designs or variations, increasing responsiveness and efficiency. Mold Customization provides a solution that balances quality and adaptability for both prototyping and large-scale manufacturing.

Durability and material selection are critical factors in mold performance. High-quality Mold Customization products are made from materials such as hardened steel or aluminum alloys, which can withstand repeated cycles without losing accuracy. Partnering with reliable Mold Customization Manufacturers ensures that molds maintain their structural integrity over time, reducing maintenance requirements and downtime. Long-lasting molds support continuous production while preserving quality and minimizing operational interruptions.

Integration with existing production lines is also important. Well-designed Mold Customization solutions align with presses, automation systems, and other manufacturing equipment, allowing smooth workflow and high throughput. Professional Mold Customization Manufacturers provide guidance on installation, optimization, and maintenance, helping factories achieve seamless integration and improved efficiency.

Industries that rely on precision components benefit significantly from working with skilled Mold Customization Manufacturers. By combining accuracy, flexibility, durability, and seamless integration, Mold Customization helps manufacturers meet production targets while maintaining high-quality standards. It allows factories to optimize operations, reduce waste, and deliver components that meet client requirements consistently.

Partnering with a Mold Customization Manufacturer provides access to expertise, great materials, and tailored solutions that enhance production processes. Implementing high-quality Mold Customization solutions supports efficiency, reliability, and adaptability, making it a strategic choice for modern manufacturing environments.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness