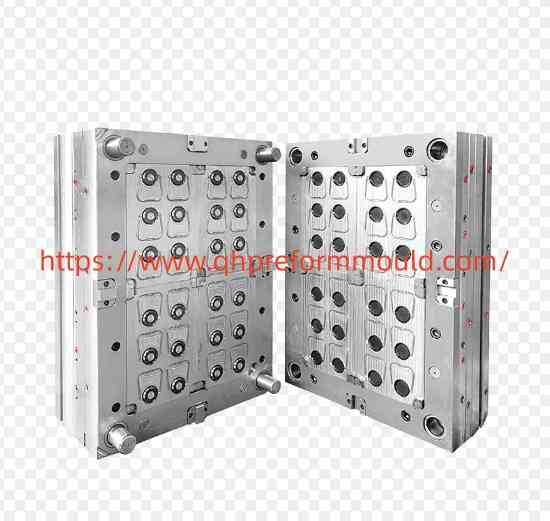

Why Is Bottle Mould Stability Important For Operational Planning qhpreformmould

Bottle Mould development reflects a continuous relationship between intention, execution, and long-term use. Every shaping decision influences not only immediate results, but also how smoothly daily operations unfold over time. Within production environments, reliability emerges from alignment rather than force, built through understanding how each stage interacts with the next.

Processes benefit when structure supports natural movement. Internal geometry that respects material behavior allows shaping to proceed calmly. When flow follows a predictable path, interruptions decrease, and consistency becomes part of routine operation rather than a goal requiring constant correction. This stability supports environments where efficiency grows from balance instead of pressure.

Workflow clarity depends on cooperation across stages. When shaping tools align with handling methods and surrounding systems, transitions become smoother. Reduced friction during movement supports steady rhythm and minimizes disruption. Over time, this coordination reinforces confidence throughout the production environment, allowing teams to focus on refinement instead of recovery.

Planning for extended use requires foresight. Tools designed with long-term application in mind maintain alignment across repeated cycles. Predictable behavior supports orderly maintenance scheduling and reduces uncertainty. This foresight allows organizations to plan calmly rather than respond reactively, strengthening operational stability.

Adaptation remains essential within evolving markets. Packaging concepts rarely remain static, and production tools must accommodate gradual change. Shaping solutions that allow adjustment without major disruption support continuity while enabling innovation. This flexibility empowers businesses to respond to new presentation ideas while preserving established workflows.

Human interaction with equipment plays a defining role. Operators work most effectively when behavior remains consistent. Familiar response patterns reduce cognitive strain and support skill development. Over time, experience accumulates, allowing teams to refine processes rather than compensate for variability. This progression contributes to sustainable working environments.

Surface quality influences more than appearance. Carefully considered internal finishing supports clean release and consistent shaping behavior. Reduced resistance across cycles supports steady operation and helps preserve structural clarity. These qualities contribute to reliability without demanding constant attention.

Integration extends beyond physical alignment. Communication between supplier and manufacturer shapes how well tools support real conditions. Clear exchange regarding usage habits, handling expectations, and future adjustments helps ensure that shaping solutions align with operational reality. qhpreformmould emphasizes this collaborative approach, prioritizing understanding and alignment over exaggerated claims.

Consistency supports trust. When tools perform predictably, planning becomes easier. Teams gain confidence in schedules, maintenance routines, and output expectations. This trust supports calmer environments where focus shifts toward improvement rather than troubleshooting.

Operational efficiency grows when systems feel cohesive. Balanced interaction across shaping, handling, and finishing stages reinforces continuity. Reduced interruption supports steady rhythm and allows each stage to contribute effectively. Over time, cohesive systems create environments where reliability becomes habitual.

Visual uniformity contributes quietly to downstream efficiency. Stable openings and balanced proportions support labeling and handling ease. These qualities influence presentation without drawing attention, reinforcing dependable appearance across varied contexts.

Durability supports responsible planning. Structural stability across extended use reduces corrective intervention and supports predictable outcomes. This reliability allows organizations to allocate resources thoughtfully and maintain clarity across operations.

Progress within manufacturing often emerges through small, consistent improvements rather than dramatic change. Tools designed with realistic understanding support this steady evolution. When shaping solutions respect both process and people, outcomes align naturally with operational goals.

For organizations seeking mould development grounded in process clarity, adaptability, and operational balance, Taizhou Qihong Mold Co., Ltd. offers experience shaped by practical insight and collaborative execution, presented clearly through https://www.qhpreformmould.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness