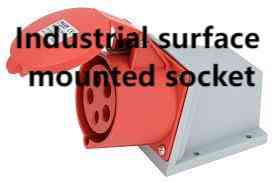

Nante Industrial Surface Mounted Socket Solutions For Heavy-Duty Sites

Choosing the right electrical outlet for a factory or workshop influences uptime, safety, and worker productivity. Smart planners often specify the Industrial surface mounted socket as a core component because it provides robust mechanical protection while remaining easy to access, and the Industrial surface mounted socket delivers a practical balance of durability and serviceability for harsh environments. This article examines materials, installation techniques, maintenance best practices, and retrofit strategies to help engineers and contractors select and deploy the correct surface-mounted power solution.

Materials and Mechanical Protection

Rugged environments demand enclosures and faces that resist impact, chemicals, and vibration. Look for housings made from die-cast aluminium or reinforced plastics with UV-stable coatings and corrosion-resistant hardware. Impact-rated bezels and recessed receptacles reduce accidental knocks from carts or tools. Gasketed seams and gasketing materials rated for compression set resistance maintain an IP rating over years of thermal cycling. For areas with heavy wash-downs or chemical exposure, additional sealing compounds and stainless fasteners will extend service life.

Mounting and Placement Considerations

Proper mounting reduces stress on connections and prevents damage. Surface-mounted units should be installed on flat, structurally sound panels or backboards using torque-specified fasteners and non-conductive spacers where electrical isolation is required. Position outlets at ergonomic heights and away from splash zones unless the unit is specifically rated for direct exposure. For mobile machinery or areas with heavy vibration, use shock-absorbing mounts and flexible conduit to minimize conductor fatigue.

Wiring Practices and Load Planning

Correct wiring and circuit planning prevent nuisance trips and long-term failures. Size conductors and protective devices to match motor starting currents and continuous loads, and group circuits logically to minimize voltage drop. Use strain-relief glands at entry points and maintain manufacturer-recommended bend radii to prevent conductor damage. Clearly label terminals and provide ample clearance inside the mounting cavity so future modifications are straightforward and code-compliant.

Safety Features and Compliance Checks

In industrial settings, compliance with electrical codes and safety standards is essential. Choose products with third-party listings where possible and ensure accessories—such as in-use covers, lockable devices, and local disconnects—meet the intended application. Incorporate ground-fault protection where personnel contact with energized parts is possible, and specify tamper-resistant or keyed options in public-access areas. Periodic inspections should include torque verification of terminations and visual checks for seal integrity.

Maintenance, Troubleshooting, And Lifecycle Value

Regular inspection and modest preventive maintenance dramatically extend product life. Create a checklist that includes gasket condition, evidence of moisture ingress, terminal torque checks, and visual signs of overheating. Replace consumables (gaskets, lens covers, and sacrificial fuses) on schedule rather than waiting for failure. For troubleshooting, thermal imaging and simple voltage-drop tests quickly identify hot connections or undersized wiring before they cause downtime. Prioritizing maintainability—such as easy access to terminals and modular component replacement—reduces long-term total cost of ownership.

Retrofit Strategies For Existing Facilities

Upgrading older installations often presents constraints: existing conduit, limited panel space, or legacy circuit layouts. Surface-mounted solutions are particularly useful for retrofits because they can be mounted without opening existing walls and accept a variety of conduit entries. When retrofitting, assess the condition of grounding and bonding systems and plan for cable routing that avoids sharp bends or pinch points. Consider modular units that allow phased upgrades—swap the outlet module first, then add advanced protective components later.

Practical On-Site Tips From Installers

Installers recommend pre-planning the cable routing and confirming accessory compatibility before arriving on site—this prevents multiple trips and costly downtime. Using pre-assembled mounting kits and labeled harnesses speeds installation and reduces wiring errors. Also, keep a small inventory of common spare parts (seals, screws, terminal blocks) at the facility; these often eliminate urgent shipping needs when faults occur.

Conclusion: Specify For Durability And Ease Of Service

In heavy-duty operations, specifying the right surface-mounted power solution improves safety, lowers maintenance time, and increases equipment uptime. Prioritize units that combine robust mechanical design, accessible wiring layouts, and service-friendly components to achieve the best lifecycle value. For product specifications, certified listings, and compatible accessories, visit www.nante.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness