Whitepaper: Enabling the Smart Factory with Predictable Tooling – The Carbide Flats Approach

The history of metal cutting is a story of seeking greater hardness. From carbon steel to high-speed steel, to the widespread adoption of tungsten carbide, and onward to ceramics and CBN, the pursuit has often been linear: find a harder material to cut a harder workpiece. But in today’s landscape of advanced materials, complex geometries, and the imperative of Industry 4.0 connectivity, hardness alone is no longer sufficient. The next leap forward lies in intelligent resilience.

At Carbide Flats, we define intelligent resilience as a tool’s holistic ability to manage the multifaceted stresses of the cutting zone—thermal, mechanical, and chemical—in a predictable and optimized manner. Our new product line embodies this philosophy, representing a paradigm shift from passive tooling to engineered performance systems.

This evolution is built on three interconnected pillars:

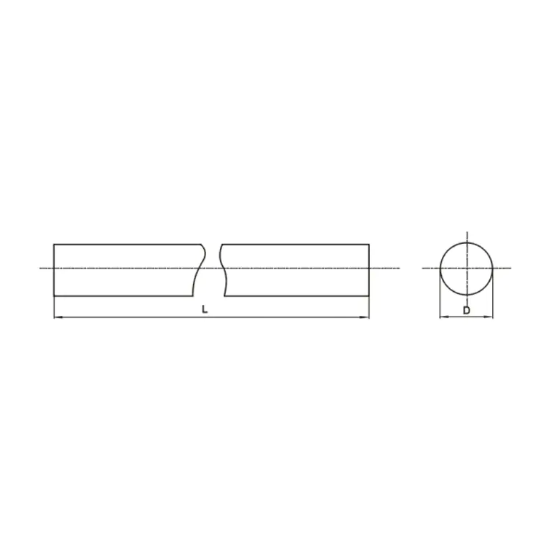

Adaptive Material Science: We no longer view carbide as a simple, monolithic material. Our proprietary Carbide Flats substrate is a micro-engineered composite, designed to channel energy and arrest crack propagation at the microscopic level. It’s a material that doesn’t just resist wear; it manages it intelligently.

Geometry as a Thermal System: The cutting edge is a furnace, generating intense localized heat. Our GeoLock™ geometry is computationally designed not just for strength, but as a heat dissipation network. It actively pulls thermal energy away from the critical edge and into the removed chip, stabilizing the cutting zone and protecting both the tool and the workpiece metallurgy.

Predictability for Digital Integration: The true value for the smart factory is predictability. A tool that fails randomly is a data black hole. A tool that wears consistently and predictably, like Carbide Flats, becomes a quantifiable asset. Its lifecycle can be modeled, its changes can be scheduled autonomously, and its performance data can feed back into adaptive process control loops.

Carbide Flats is more than a durable insert; it is a platform for stable, predictable, and optimized machining. It answers the call of modern manufacturing, where reducing variance is as crucial as increasing speed. As we move towards increasingly autonomous production, the tool itself must become smarter. With Carbide Flats, the future of intelligent, resilient machining is here, and it’s ready to cut.

Explore the technical data and the science behind intelligent resilience in our full whitepaper, available for download on the Carbide Flats resource page.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness