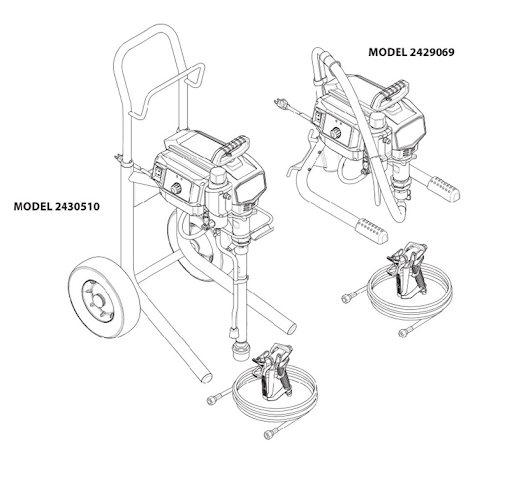

Titan Impact X 440 Parts Diagram for Smooth Maintenance

Maintaining a paint sprayer is the key to keeping an even flow on all of your projects. The Titan Impact X 440 is a powerful and reliable sprayer, but just like any tool, it runs best when you maintain its parts. An easily viewable titan impact x 440 parts diagram gives owners insight into the operation of every part on the machine, as well as how to properly maintain their investment. Now, take that with high-quality replacement parts that we will provide for you when it comes time to do maintenance, and you can feel pretty good about yourself because all of the things are very easy, quick, and have a low margin of error.

Why a Parts Diagram Matters

On the surface, a sprayer appears to be a rather simple machine, but inside it is laden with interconnected components that have to work in unison. Without a good diagram, keeping things in order can feel confusing. The parts schematic provides a visual reference point. It displays where everything sits, how pieces attach, and which parts are particularly crucial to the sprayer’s pressure, flow, and performance.

When you have a full view of the layout, you eliminate guesswork. You can identify issues early, change out worn pieces properly , and limit downtime. The result is smoother projects and fewer surprises in the middle of a job.

Understanding the Main Components

There are a few critical components of each Titan Impact X 440 that determine how the sprayer operates to pump and spray paint. The drawing often shows the motor, piston assembly, fluid section, inlet and outlet valves, and pressure control mechanism.

The entire system is driven or powered by the motor. It operates the fluid section by stroking the piston to force paint through it. The valves ensure the paint goes in one direction. The pressure regulating knob allows you to. These components are the core of the machine. Once any part gets worn or clogged up, the entire sprayer pays for that.

The illustration makes it a snap to trace the path of paint from the hose to the gun. 7And with that kind of clarity, looking after it just makes more sense.

Spotting Wear and Tear Early

Sprayers are operated under high pressure, and this pressure wears out seals, tips, valves, and filters for these sprayers. The diagram provides a guide to the places that typically require attention. Seals go first because they’re the ones that deal with movement all the time. Filters also have to be cleaned regularly, since they’re what capture the fine particles of paint-colored dust. Spray orifices wear and get larger over time, leading to uneven application.

Inspection can be done in the right order by referring to the diagram. This ensures that problems don't get missed, and you have records of which parts were removed and when.

Replacing Parts With Confidence

Most people are really nervous when it comes to changing parts in their sprayer. The Titan Impact X 440 paint sprayer parts diagram takes away that worry. It illustrates how all the parts interlock as part of the system. You can see the angle, the connecting points, and the bolts that hold each one together.

The fit is perfect when you utilize this original replacement part from All Titan Parts. This cut down the leaking, clogging, and loss of pressure. It also prevents overworking the motor. If you use the wrong part, you may weaken the sprayer, but if you have the correct one down to a science, this is an easy repair.

Keeping the Fluid Section Clean

And the fluid section is where paint moves, so it’s getting dirty first. The full contents of this section are shown in the diagram. This comprises the piston rod, the cylinder, the packing set, and the inlet and outlet valves.

The hard buildup of paint is avoided if these parts are cleaned periodically. This sprayer makes a good stroke when these regions are clean. The pump stays quieter. The pressure remains consistent. With your diagram as a reference, you can carefully take each piece out and return it to its rightful place without confusion.

Understanding the Pressure System

This pressure system dictates how the sprayer will dispense paint. If the pressure spikes, falls, or fluctuates at all, you will get uneven coats out of your sprayer. The pressure control knob, micro-switch , and the pressure spring are illustrated on the diagram.

Understanding how these parts fit together allows you to make proper adjustments to the sprayer. It also allows you to "see" when a part needs to be replaced. Take care of the motor and avoid overloading the pump by maintaining it properly.

Conclusion

Your best source for Titan Impact X 440 parts diagram. It teaches you a little about each part, how to monitor wear on the parts, replace each part properly, and prevent damage. And with the help of authentic replacement parts from All Titan Parts, the sprayer remains powerful and effective for any job. With the correct information and confidence in choosing parts, you can rest assured that keeping your Titan airless sprayer in optimal condition is easy to achieve.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness