Why Self Drilling Anchor Systems Boost Safety in Modern Mining

Mining has always been one of the world’s most demanding and high-risk industries. As operations go deeper and geological conditions become more unpredictable, maintaining structural stability becomes a top priority. This is where advanced reinforcement technologies, especially self drilling anchor systems, play a game-changing role. These systems have transformed underground support practices, providing faster installation, higher load capacity, and enhanced overall site safety.

In modern mining, where efficiency and worker safety go hand-in-hand, self drilling anchor solutions have become indispensable. Trusted brands like Argentium are pushing boundaries by offering durable, reliable, and easy-to-install SDA systems that meet the safety demands of complex mining environments.

In this guest post, we dive deep into why self drilling anchors are critical to enhancing safety in mining, how they work, their benefits, and why choosing the right brand, like Argentium, can make all the difference.

Understanding the Role of Self Drilling Anchor Systems in Mining

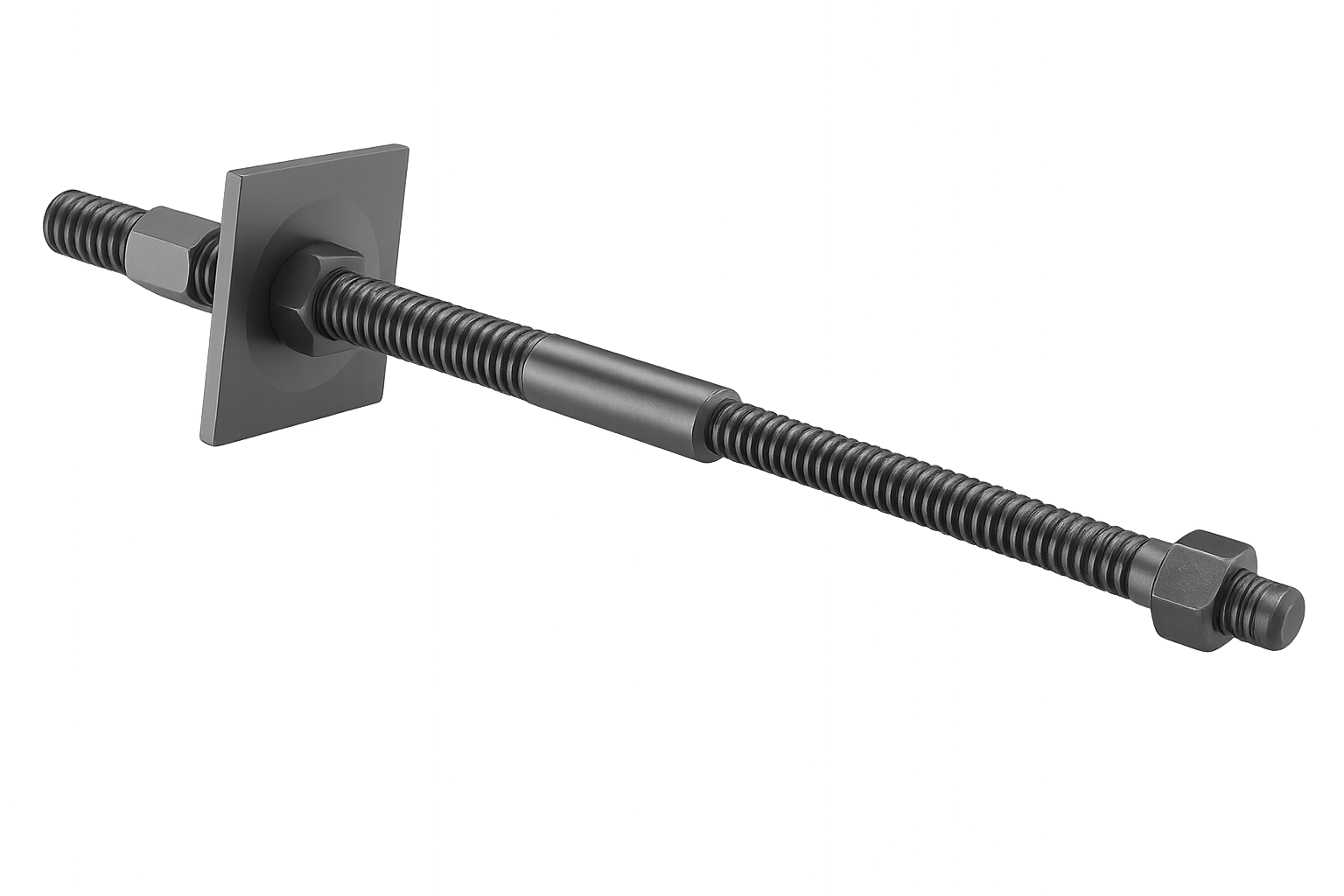

The self drilling anchor system is a structural support technology used to stabilize weak rock, fractured ground, and loose soil in underground mines. Unlike traditional anchoring methods, SDA systems do not require pre-drilling. Instead, the drill bit is attached directly to a hollow, threaded anchor bar that simultaneously drills and grouts in place.

This integrated design eliminates multiple steps, making the reinforcement process faster, safer, and more efficient, especially in unstable geological conditions.

How It Works: A Quick Breakdown

-

Drilling and grouting occur in a single step

The hollow core allows grout to be pumped through as the bar drills, ensuring complete encapsulation. -

The drill bit stays in place

This helps anchor the bar firmly into soft or fractured rock. -

Immediate load-bearing capability

This allows mining teams to move forward confidently without long waiting times.

The simplicity and reliability of the self drilling anchor design make it ideal for environments where ground conditions cannot be easily predicted.

Why Safety Depends on Better Ground Support

Mining faces constant geological risks, weak strata, high stress zones, seismic disturbances, water ingress, and falling rock. Traditional bolting methods often require multiple steps, specialized machinery, and additional labor. This increases exposure to hazards.

A self drilling anchor reduces these risks by enabling rapid and efficient reinforcement. Workers spend less time in exposed zones, and the support structure stabilizes the area much faster.

Key Safety Issues in Mining That SDA Systems Solve

-

Rockfalls due to unstable ground

-

Collapse risks in deep excavation zones

-

Delays that keep workers inside danger areas longer

-

Uneven or unpredictable rock formations

-

Water seepage weakening underground walls

By reinforcing the ground at an early stage, the self drilling anchor creates a secure working environment, reducing accidents and improving long-term mine stability.

Top Safety Benefits of Self Drilling Anchor Systems

1. Faster Installation Minimizes Exposure to Hazards

Time is one of the biggest safety factors underground. The fewer hours workers spend installing support systems, the lower the risk of accidents.

A self drilling anchor eliminates separate drilling, rod insertion, and grouting steps. This means faster reinforcement, allowing mining teams to move forward with operations safely and efficiently.

2. Enhanced Stability in Weak and Fractured Rock

Unstable geological formations are common in deep mines. SDA systems provide strong support because:

-

The drill bit remains embedded

-

Full-column grouting reinforces the entire borehole

-

The anchor bar has high tensile and shear strength

This ensures superior stability compared to conventional bolts.

3. Reduced Equipment Needs = Lower Operational Risk

Traditional rock bolting requires multiple tools and machines, increasing operational complexity. With a self drilling anchor, mining teams use fewer tools and perform fewer steps. Less equipment movement underground reduces the likelihood of mechanical failures and accidents.

4. Suitable for Water-Rich or Loose Ground Conditions

Water or loose soil can cause borehole collapse during conventional drilling. SDA systems overcome this by drilling and grouting simultaneously. Since the hole is continuously filled with grout, it remains stable, even in highly challenging environments.

5. Better Load Transmission Ensures Long-Term Safety

Ground pressure intensifies as mines go deeper. A self drilling anchor provides better load distribution and carries higher capacities, which helps maintain long-term stability of tunnels, walls, and ceilings.

Why Self Drilling Anchor Systems Are the Future of Safe Mining

As mining companies adopt more advanced technologies, the goal is not just to improve production but also to minimize risk. Self drilling anchors align perfectly with this mission.

Trend toward automation and efficiency

Modern mining relies on smart equipment and automated systems. SDA systems integrate well with automated drilling rigs and robotic arm tools, reducing manpower requirements and improving safety.

Suitable for deeper and more complex mines

With deeper mining comes increased stress and ground instability. The superior bonding and support offered by self drilling anchors help maintain structural integrity even in extreme conditions.

Consistency and reliability with brands like Argentium

Quality matters. A self drilling anchor must be reliable, durable, and tested for real-world stress. Trusted brands like Argentium ensure that their SDA systems meet international safety standards, making them a preferred choice among engineers and mining professionals.

How Argentium Enhances SDA Performance and Safety

When choosing an SDA supplier, durability, quality, and engineering precision are crucial. Argentium stands out by delivering products that provide:

-

High corrosion resistance

-

Superior tensile strength

-

Flexible design options for varying rock conditions

-

Reliable and uniform grout flow

-

Long-lasting reinforcement durability

By integrating innovative designs and quality materials, Argentium’s self drilling anchor systems help mining companies achieve both safety and operational efficiency.

Real-World Applications of SDA Systems in Mining

1. Underground Tunnels

In tunnel construction, weak rock layers are common. SDA systems provide immediate structural reinforcement and prevent tunnel collapse.

2. Slope Stabilization

Open-pit mines often face landslide risks. Self drilling anchors help secure slopes and prevent soil movement.

3. Roof and Wall Support

In underground mines, ceilings and walls face constant pressure. SDA systems provide strong holding capacity to prevent rockfalls.

4. Water-Heavy Zones

In mines with water ingress, self drilling anchors prevent borehole instability and maintain secure support.

These applications underline the importance of the self drilling anchor in maintaining safe mining operations across various conditions.

Conclusion

Safety in mining is not optional, it’s essential. As geological risks increase and mining becomes more complex, modern reinforcement solutions must evolve. The self drilling anchor has emerged as one of the most reliable tools in ground support, offering faster installation, superior load-bearing capacity, and unmatched adaptability to unstable conditions.

Brands like Argentium continue to innovate, helping mining companies stay ahead with high-quality SDA systems that ensure long-term safety and structural stability. By adopting self drilling anchors, mining operations not only protect their workers but also improve productivity and sustainability.

If your mining project demands efficiency, strength, and enhanced safety, self drilling anchor systems are the future.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness