TPU Compound Film Processing Technology Overview

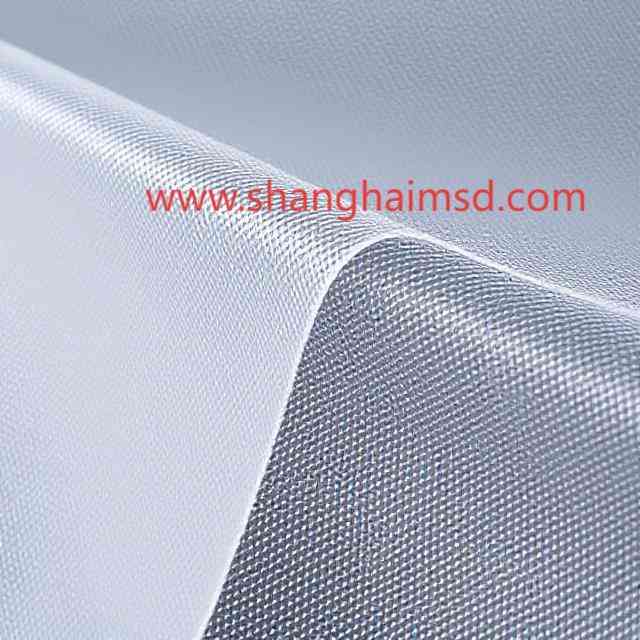

Among modern polymer materials, TPU Compound Film has become one of the most innovative and versatile materials due to its remarkable mechanical properties, optical clarity, and environmental resilience. This thermoplastic polyurethane composite combines elasticity, toughness, and resistance to wear in a single formulation, providing engineers and designers with a balance of strength and flexibility that is difficult to achieve with traditional films. Its intrinsic material design allows it to perform exceptionally well under stress, making it ideal for demanding applications across multiple industries.

The performance of TPU films originates from their unique segmented molecular structure, consisting of alternating soft and hard segments. The soft segments, formed from long-chain polyols, deliver flexibility and low-temperature performance, while the hard segments derived from diisocyanates contribute to rigidity and thermal stability. The interaction between these two phases creates micro-domains that allow TPU to behave like both an elastomer and a thermoplastic. This duality gives the material outstanding energy absorption, impact resistance, and recoverability after deformation, ensuring long-term reliability under cyclic mechanical stress.

Another key attribute of TPU Compound Film is its excellent resistance to abrasion, chemicals, and hydrolysis. Compared to PVC or EVA films, TPU maintains structural integrity even in humid, high-temperature, or solvent-exposed environments. This resistance makes it suitable for industrial belts, protective layers, and outdoor applications where mechanical wear and environmental degradation are common concerns. The film’s inherent UV stability further extends its service life, ensuring that products made with TPU maintain their aesthetic and functional qualities even after prolonged outdoor use.

Thermal adaptability is another defining characteristic. TPU films maintain flexibility over a wide temperature range—from sub-zero conditions to high heat—without cracking or deformation. This makes them ideal for automotive interiors, flexible seals, and outdoor gear exposed to temperature fluctuations. Additionally, TPU’s high elongation at break allows it to conform to complex shapes without tearing, enabling manufacturers to create seamless or contoured products through thermoforming and vacuum molding.

The film’s optical transparency and clarity are crucial in industries where visual quality and precision matter. TPU films can achieve near-glass transparency, allowing their use in display protection, medical packaging, and consumer electronics. Their surface gloss and optical purity make them suitable for lamination with decorative layers or for use as protective overlays. Furthermore, TPU’s low haze and excellent light transmission support its integration into applications that demand both visual appeal and high performance, such as flexible screens and transparent protective gear.

From a functional standpoint, TPU films also demonstrate outstanding adhesion and compatibility with other materials. This enables the creation of multi-layer composites where TPU serves as either the bonding or surface layer. Its natural polarity ensures strong interfacial adhesion without requiring aggressive chemical primers. Combined with anti-fog or anti-scratch coatings, TPU films provide enhanced performance in automotive dashboards, sports equipment, and medical devices, where clarity and durability are essential.

Environmental compatibility adds further value to TPU films. Unlike PVC, TPU does not require plasticizers or chlorine-based compounds, making it safer and more sustainable. It can be recycled through re-melting and reprocessing, allowing manufacturers to reduce waste and support circular economy practices. As industries move toward greener materials, TPU’s balance of durability, flexibility, and recyclability positions it as a leading alternative for environmentally responsible product design.

Shanghai Ming Shida International Trading Co. specializes in delivering high-quality TPU compound films engineered for a wide range of applications. The company’s expertise in polymer science, combined with advanced production capabilities, ensures products that meet global standards for performance, safety, and sustainability. Through continuous research and collaboration with international partners, Shanghai Ming Shida remains a trusted source for innovative TPU materials that empower industries to achieve higher performance with lower environmental impact.For more details, visit https://www.shanghaimsd.com/news/the-composition-and-versatility-of-tpu-compound-film.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness