Rigid Boxes: Structure, Function, and Significance in Modern Packaging

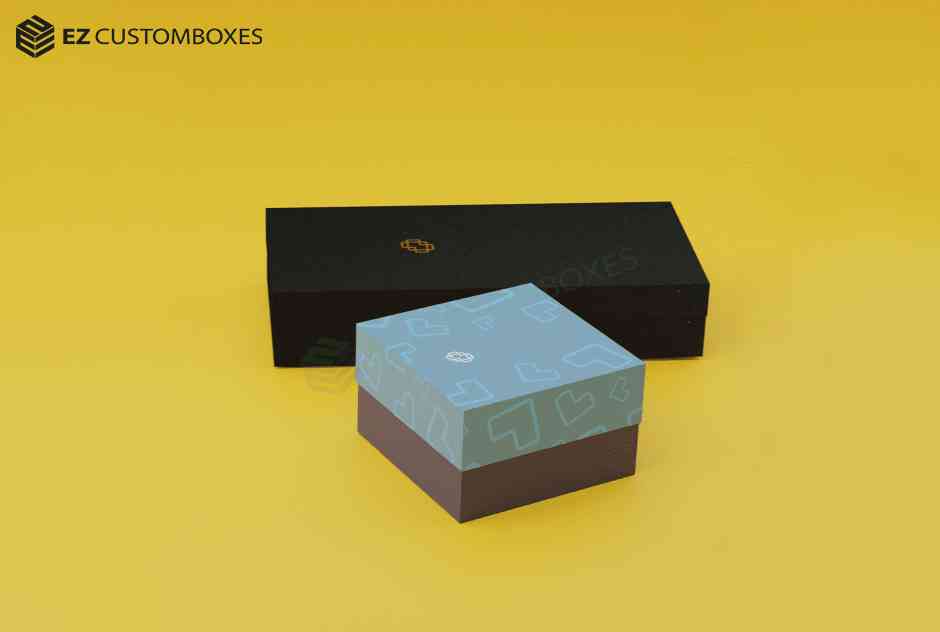

Packaging is a fundamental element of modern commerce, serving functions that extend far beyond protection. It communicates identity, conveys information, and shapes how consumers perceive products. Among the many types of packaging used today, rigid boxes. Known for their durability, premium appearance, and structural integrity, rigid boxes are widely used in industries such as cosmetics, electronics, luxury fashion, and consumer goods.

What Is the Takeout Paper Bag Size

Takeout paper bag size varies depending on the type of food and container. Common sizes include small (8" x 4" x 10"), medium (10" x 5" x 13"), and large (12" x 7" x 17"). These bags are designed for strength, convenience, and sustainability in food delivery and packaging.

Unlike folding cartons or corrugated packaging, rigid boxes are made from thick paperboard or chipboard that is not meant to collapse or fold. This design gives them strength and a refined appearance suitable for high-value products. Over time, rigid boxes have evolved from simple protective shells into sophisticated design tools that balance functionality, sustainability, and branding. This essay explores their structure, manufacturing process, materials, design principles, sustainability issues, and role in consumer perception.

1. Structural Characteristics and Core Functions

1.1 Structural Integrity

Rigid boxes are constructed from dense paperboard, typically ranging between 800 and 1500 grams per square meter (gsm), laminated with decorative paper. This multi-layer structure provides substantial rigidity, protecting delicate or expensive items. Because the material does not fold easily, rigid boxes maintain their shape throughout handling and storage, ensuring consistent presentation.

1.2 Product Protection

One of the key purposes of rigid boxes is to safeguard products from external pressure, moisture, and accidental impacts. Electronics, perfumes, and jewelry often rely on rigid packaging to prevent damage. Internal supports such as foam inserts, molded pulp trays, or cardboard dividers enhance this protective function.

1.3 Presentation and Unboxing

Rigid boxes contribute to the perceived value of a product by offering a controlled, deliberate unboxing experience. The resistance of the lid, the texture of the materials, and the precision of the fit all create a sense of care and craftsmanship. For many luxury goods, the box becomes part of the product itself, influencing emotional connection and perceived quality.

1.4 Longevity and Reusability

Due to their durability, rigid boxes are often kept and reused by consumers for storage or decorative purposes. This extended lifecycle reinforces brand visibility and reduces waste, adding both functional and environmental value.

2. Materials Used in Rigid Box Manufacturing

The materials selected for rigid boxes affect their strength, cost, recyclability, and tactile qualities. Several types of materials are commonly employed:

2.1 Paperboard (Chipboard or Greyboard)

The structural base of most rigid boxes is paperboard, also known as chipboard or greyboard. It is produced by compressing recycled paper pulp into dense sheets. Its rigidity makes it ideal for supporting weight and maintaining form. The outer surfaces are then covered with printed or textured paper to create a polished appearance.

2.2 Wrapping Paper

Decorative wrapping paper enhances visual and tactile appeal. It can be plain, printed, embossed, or coated with finishes such as matte or gloss lamination. The wrapping paper is glued to the rigid board to conceal seams and create a continuous surface.

2.3 Liners and Inserts

Interior linings are often made from velvet, satin, paper, or foam to protect products from scratches and hold them securely. The choice of insert depends on the product’s weight, shape, and sensitivity.

2.4 Adhesives and Coatings

High-quality adhesives ensure that the wrapping paper adheres smoothly without bubbling or peeling. Water-based glues are increasingly favored for environmental reasons. Optional coatings such as anti-scratch film or UV varnish can increase durability.

3. Types and Structures of Rigid Boxes

Rigid boxes come in multiple structural designs to suit various functions and aesthetics.

3.1 Telescope Boxes

A classic style consisting of a base and a separate lid that fits over it. Common examples include smartphone boxes and gift boxes. Variations such as partial-telescoping designs allow for easier opening.

3.2 Magnetic Closure Boxes

These boxes feature concealed magnets embedded in the flap, offering a seamless closing mechanism. They combine practicality with a modern appearance and are widely used for luxury retail packaging.

3.3 Drawer Boxes (Slide Boxes)

Comprising an outer sleeve and an inner sliding tray, drawer boxes provide smooth functionality and enhanced protection. They are popular for cosmetics, accessories, and chocolates.

3.4 Hinged Boxes

In hinged designs, the lid is attached to the base with a paper or fabric hinge. They open like books, offering an elegant and convenient presentation.

3.5 Collapsible Rigid Boxes

Although traditional rigid boxes are non-folding, innovations have led to collapsible designs. These use concealed magnets or folding joints that allow them to flatten for transport, reducing shipping costs while maintaining premium quality when assembled.

4. Manufacturing Process

Producing a rigid box involves precision and craftsmanship. The process typically includes several key stages:

4.1 Cutting and Creasing

Large sheets of paperboard are cut into panels according to design specifications. Creasing marks are applied where edges will be folded or joined, ensuring sharp, clean corners.

4.2 Mounting

Printed or decorative wrapping paper is laminated onto the paperboard panels using adhesive. This step defines the visual and tactile appearance of the box.

4.3 Assembling

The laminated boards are folded and glued into the final shape. Corners may be reinforced with additional paper or fabric strips for strength and accuracy.

4.4 Drying and Finishing

Boxes are dried to secure the adhesive, then trimmed and inspected for quality. Additional finishing techniques, such as foil stamping or embossing, may be applied at this stage.

4.5 Quality Control

Each box is examined for alignment, surface smoothness, and printing accuracy. High-end brands often implement multiple inspection steps to maintain consistency across large batches.

5. Design and Aesthetic Considerations

Rigid boxes play a critical role in visual branding. Design choices directly influence consumer expectations and perceived value.

5.1 Color and Visual Balance

Color palettes are selected to reflect brand identity. Neutral or muted tones often convey sophistication, while vibrant colors can emphasize creativity or youthfulness. Balanced contrast between exterior and interior colors enhances visual appeal.

5.2 Typography and Graphics

Typography communicates tone and readability. Clean, legible fonts maintain professionalism, while subtle logos or embossed brand marks add refinement without overwhelming the design.

5.3 Texture and Surface Finishes

Surface texture contributes to the sensory experience. Techniques include:

-

Matte lamination: a soft, non-reflective finish.

-

Gloss lamination: a bright, reflective surface.

-

Soft-touch coating: a smooth, velvety texture.

-

Embossing/debossing: raised or recessed text or imagery.

These treatments make the box both visually distinctive and pleasant to handle.

5.4 Structural Simplicity

Minimalist structures are preferred in modern design for efficiency and ease of recycling. Clean edges, uniform folds, and proportionate dimensions enhance precision and practicality.

6. Branding and Market Positioning

Rigid boxes often serve as a visual extension of the brand’s identity.

6.1 Perceived Value

Consumers frequently associate rigid boxes with exclusivity and quality. The structural sturdiness and tactile sensation communicate attention to detail, reinforcing the idea that the enclosed product is valuable.

6.2 Consistency Across Product Lines

Maintaining consistent design features across multiple products strengthens brand recognition. Subtle variations in color or material can distinguish product categories while preserving coherence.

6.3 Customization and Differentiation

Advances in digital printing and die-cutting enable brands to customize small batches economically. Personalized packaging designs for limited editions or seasonal collections help products remain distinctive.

7. Sustainability and Environmental Considerations

As environmental awareness increases, manufacturers are rethinking the materials and processes used in rigid box production.

7.1 Recycled and Biodegradable Materials

Using recycled greyboard or post-consumer paper reduces the demand for virgin fiber. Many producers now offer biodegradable coatings and glues to make boxes easier to recycle.

7.2 Minimalism and Resource Efficiency

Design strategies that eliminate unnecessary layers or components reduce overall material use. Lighter paperboard grades can still provide structural stability when engineered properly.

7.3 Eco-Friendly Printing

Soy-based and water-based inks are being adopted to replace petroleum-based options, lowering emissions and improving recyclability.

7.4 Reusability

Because rigid boxes are durable, they naturally lend themselves to reuse. Encouraging reuse through aesthetic longevity and multi-purpose design contributes to waste reduction.

7.5 Life-Cycle Design

Some manufacturers are exploring cradle-to-cradle systems, where packaging materials can be recovered and reprocessed, supporting circular economic principles.

8. Industry Applications

Rigid boxes are used across multiple sectors due to their versatility and high-quality presentation.

8.1 Luxury Goods

Jewelry, watches, perfumes, and fashion accessories often rely on rigid boxes to reflect exclusivity. Their sturdiness and finish align with the expectations of premium markets.

8.2 Electronics

Products such as smartphones, headphones, and tablets require packaging that protects against impact while showcasing the brand’s precision. Rigid boxes offer both structural strength and aesthetic quality.

8.3 Food and Confectionery

High-end chocolates and specialty foods are often presented in rigid boxes with food-safe liners. These boxes enhance perceived quality and serve as keepsake containers.

8.4 Corporate and Gift Packaging

Rigid boxes are widely used for corporate gifts, awards, and promotional items. Their reusability adds long-term value to the presentation.

8.5 Stationery and Lifestyle Products

Notebooks, pens, and personal accessories often use rigid boxes to maintain shape and appeal over time, complementing their use as both functional and decorative objects.

9. Challenges in Production and Supply

Despite their advantages, rigid boxes present several production and logistical challenges.

9.1 Cost

The high density of materials and multi-step assembly process make rigid boxes more expensive than folding cartons. Labor-intensive manual work often contributes to higher costs.

9.2 Space and Transportation

Because rigid boxes cannot be fully flattened, they require more storage and shipping space, leading to higher transportation costs. Collapsible designs are mitigating this issue.

9.3 Material Waste

Precise cutting and lamination can generate waste if not managed carefully. Efficient layout design and recycling systems are essential to minimize environmental impact.

9.4 Scalability

Maintaining uniform quality at large production scales requires careful process control. Variations in glue application or wrapping alignment can affect consistency.

10. Consumer Psychology and Perception

Packaging strongly influences consumer behavior, especially in premium product categories.

10.1 First Impressions

The rigidity and craftsmanship of the box create an impression of reliability before the product is even used. Consumers often interpret such tactile qualities as indicators of product quality.

10.2 Emotional Association

The act of opening a rigid box, with its deliberate motion and structured resistance, creates anticipation and satisfaction. This psychological response can enhance brand attachment.

10.3 Trust and Authenticity

High-quality packaging reassures consumers of authenticity, particularly in sectors vulnerable to counterfeit products. Structural precision and fine printing contribute to perceived legitimacy.

10.4 Long-Term Interaction

Since many consumers reuse rigid boxes for storage, the packaging remains part of their daily environment. This ongoing interaction extends brand exposure beyond the point of sale.

11. The Future of Rigid Box Design

Innovation in rigid box production is increasingly shaped by digital technology and environmental responsibility.

Smart packaging features such as scannable QR codes or embedded NFC chips are being integrated to provide information, verify authenticity, or enhance consumer engagement. Automation in cutting and gluing processes is improving production efficiency and consistency.

Sustainability will continue to guide design choices. The use of renewable fibers, compostable coatings, and collapsible structures points toward a future where rigid boxes maintain their visual and functional strengths while minimizing ecological impact.

How To Measure Box Dimensions & Package Size

To measure box dimensions and package size, record the length, width, and height in inches or centimeters. Measure the length as the longest side, width as the shorter side, and height from base to top. Accurate box dimensions ensure proper fitting, efficient shipping, and cost-effective packaging solutions.

Conclusion

Rigid boxes represent a fusion of functionality, aesthetics, and craftsmanship. Their structural integrity provides reliable protection, while their refined appearance enhances the perceived value of products. Across industries, they serve as both a practical and symbolic component of brand identity.

As technology advances and environmental expectations rise, rigid packaging are designed is moving toward more efficient and sustainable models. Recycled materials, modular structures, and smart integration will define the next generation of packaging.

Ultimately, the appeal of rigid boxes lies in their ability to balance durability with design sophistication. They embody the evolving role of packaging as not merely a container but a medium of communication—bridging product, brand, and consumer experience in an increasingly conscious marketplace.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness