PC Hollow Sheets: The Cutting-Edge Material Transforming Modern Construction

Wherever one looks to find more modern materials for the building sector, hollow PC sheets are among the first ones to come to mind as a very diversified and long-lasting solution for almost any kind of a project. In fact, these panels are made of polycarbonate, a special thermoplastic which can stand against any kind of impact, stay almost totally clear, and are able to endure even the most extreme weather conditions. Apart from that, the design of a hollow core not only makes the product less heavy but also gives it far better heat-insulating characteristics, hence these panels can easily be used as a glue of both the architecture and the interior. While the construction industry is on its way to the use of eco-friendly, lightweight, and high-quality materials, hollow sheets of PC are still a silent candidate that successfully mixes the old with the new by not only meeting but also going beyond the requirements of contemporary designs. The fact that they can perfectly fit into any environment and project is still a major factor that keeps their popularity growing and spreading in different areas, namely commercial, industrial, and residential sectors.

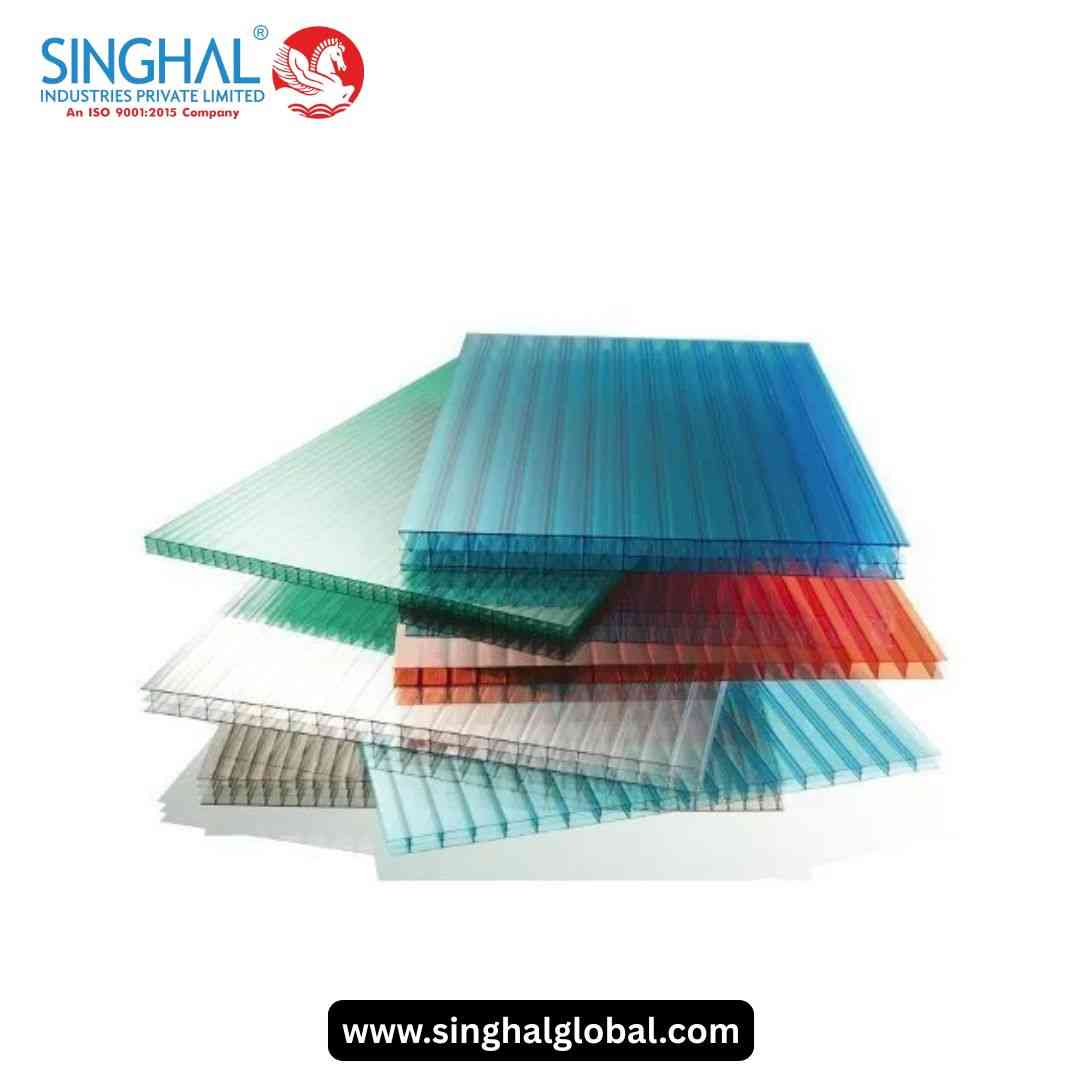

Understanding the Unique Qualities of PC Hollow Sheets

One of the most important features of a PP hollow sheet is its revolutionary structure of the hollow core, bringing strength and lightness in perfect harmony. Stemming from a single extrusion operation, the sheet comes with a number of hollow chambers of the same size that greatly bring down the total weight but at the same time high impact resistance is retained. The impact resistance in this case comes largely from the polycarbonate being a quite strong material by itself and hence it is almost indestructible when the conditions are normal. Besides that, PC hollow sheets are superbly resistant to UV radiation, thus, they can handle, to say the least, sun exposure without getting discolored or weakened. The main reason for that is their high optical clarity which can let in maximum natural light so these sheets can be used for skylights, greenhouses, roofing that is transparent, etc. Not only that but also their heat insulating features assist in ventilating the inside space, lowering the energy demand, and thus, making it more environmentally friendly. All the features put together represent the PC hollow sheets as an innovative product that is meant to gradually replace the traditional building materials in the future of the construction industry.

Diverse Applications and Advantages of PC Hollow Sheets

PC hollow sheets have a great number of uses that are not limited only to sun protection by means of a roof. With the help of these materials, the development of new types of buildings is even possible, for example, shed transparent walls, building partitions, sound barriers, and decorative facades. They, being a lightweight, get transported and installed without any heavy machinery, thus the expenses on labor and duration of the project both get lowered. In case of breakage, PC hollow sheet, due to their high impact resistance, will cause less harm than the traditional glass, which is the reason why they are a safer substitute for glass usage in particular where security is first and foremost, e.g., schools, hospitals, and sports complexes. The impact resistance could be one of the reasons that shattering is avoided so if the latter happens, those inside will be safe. On top of that, their being resistant to different atmospheric factors allows them to have a pretty long life even if they are in a hot and dry area, where they will not corrode, nor absorb water, nor get affected by any alkalis. Since they are able to scatter the incoming natural light, these materials are at the same time good for the prevention of direct sunlight inside a room and also for rivalling the internal light with the external.

PP Hollow Sheets: An Alternative Worth Considering

While PC hollow sheets are the primary choice in most cases, PP hollow sheets are gradually becoming a viable cheaper alternative in some areas. Comprising polypropylene, these panels imp are highly resistant to chemicals, and thus can be used in conditions that are rigorously exposed to moisture, acids, or other chemicals. They have a decent impact strength and are light in weight; however, in general, their impact resistance and UV stability are not up to the level of PC ones. PP hollow sheets find the most application in the packaging, signage, and interior partitions areas, where chemical exposure or moisture resistance is a priority. Being low priced makes them very appealing to those projects where there is a lack of sufficient funds; nevertheless, they are not good enough for outdoor uses where long-lasting UV exposure is required. Selection between PC and PP hollow sheet should be made after very careful scrutiny of environmental factors, durability and budget requirements to arrive at the right material choice.

Environmental Sustainability and Future Prospects

The issue of sustainability keeps more and more people aware of the green construction materials they choose. PC hollow sheets are recyclable as well as recyclable polycarbonate resins can be utilized in their production, thereby lessening the carbon footprint. Their robustness is a guarantee for a long service life making the need for replacement and thus waste generation very low. What is more, by means of their thermal insulation properties, the energy consumption of the buildings is reduced, making them in line with green building standards. Their eco-friendlier environmental profile is being supported by further improvements in their production process, e.g. the bio-based polycarbonates and the green coatings. While PP hollow sheets are far from to be as recyclable as PC ones, the researches conducted have the goal to hike their sustainability as well. With the advent of climate-conscious building practices, which have become mainstream, a need for environment-friendly hollow sheet materials would be created, thus PC hollow sheets would be the choice that leads to sustainable construction solutions.

Conclusion

In summary, PC hollow sheet is tomorrow's building material, assimilating light weight, impact resistance, and environmental respect. Their longevity, clarity, thermal resistance, and ease of application make them attractive for countless applications ranging from safety shields and skylights to decorative cladding and acoustical barriers. PP hollow sheet provides a good choice when budgets are reduced with desirable chemical resistance, but PC sheet’s improved impact resistance and UV longevity make it the best potential candidate when considering outdoor, high-impact, or critical-safety situations. In process with sustainability and continual production innovations, PC hollow sheets will become even more integrated into future construction practices. Finally, their optically pleasing properties will ensure that, while providing high performance, they happen to meet the aesthetic requirement of future architectural endeavors, ensuring that they will still be one of the primary materials for the development of future architecture.

Frequently Asked Questions

-

What is a PC hollow sheet and why is it used commonly in construction?

A PC hollow sheet is a plastic polycarbonate panel containing hollow spaces that provide it with the properties of being light-resistant, high light-transmitting, and heat-insulating, thus, it is the ideal material for roofing, partitions, and decorative applications. -

In what ways is a PP hollow sheet different from a PC hollow sheet?

PP hollow sheets are manufactured from Polypropylene, thus, they are chemically resistant and low-priced, however, generally, they are less impact-resistant and have lower UV stability than PC sheets. -

Are PC hollow sheets environmentally friendly?

Indeed, they can be recycled and made from recycled resins. Their longevity and energy-saving features also help to lower CO2 emissions, which is in line with green building principles. -

What are the main advantages of using PC hollow sheets?

The major reasons are impact resistance, light-weighted design, UV stability, high transparency, thermal insulation, and facility of installation. -

Can PC hollow sheets withstand extreme weather?

Indeed they are. They are made in a way to endure UV degradation, and temperature changes and are not affected by moisture, and therefore are suitable for permanent outdoor uses. -

Who is the largest supplier of PC Hollow Sheets?

Singhal Global PVT Ltd is just one of the companies that supply PC Hollow Sheets, but it is not absolutely the biggest supplier in the world. -

Who is the largest exporter of PC Hollow Sheets?

Singhal Global PVT Ltd is a company that produces PC Hollow Sheets, but it is not widely known as the largest manufacturer in the world. -

Who is the largest manufacturers of PC Hollow Sheets?

Singhal Global PVT Ltd is one of the manufacturers of PC Hollow Sheets, but it is not generally recognized as the largest manufacturer worldwide. -

What factors should influence the choice between PC and PP hollow sheets?

Decision-making could be mainly influenced by Environmental exposure, impact resistance, chemical resistance, budget limitations, and aesthetic preferences. -

What does the future hold for hollow sheet materials?

There will be continuous research on bio-based polycarbonates, environmentally friendly coatings, and improved UV resistance, which will ultimately lead to a wider application of these products in the field of sustainable construction.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness