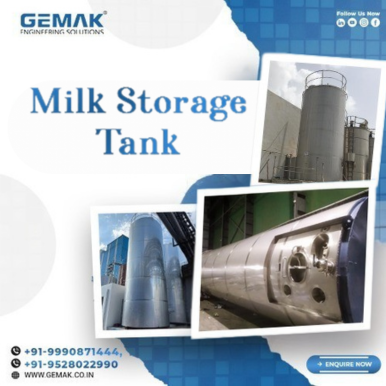

Essential Features of a Stainless Steel Milk Storage Tank

Hygiene, durability, and efficiency occupy an altogether different sphere in dairy processing and storage. The Stainless Steel Milk Storage Tank acts as an employment of value in keeping the milk's quality intact from collection to process. Gemak Engineering Solutions acknowledges the peculiar problems faced by the dairy industry and aims to provide lasting solutions. In this blog, we will focus on an important few features sought by buyers and dairy professionals when purchasing stainless steel milk storage tanks for their business.

Why is Choosing the Right Milk Storage Tank Important?

Milk is a highly perishable commodity and therefore needs proper handling and storage to retain its nutritional and microbial integrity. Any neglect with respect to storage will lead to the spoilage of the product and potential health hazards. Hence investing in the proper stainless steel milk storage tank becomes a matter of ensuring the safety of the public as preservation of product quality is concerned. Additionally, this is a matter of operational efficiency.

1. Good Material and Resistance to Corrosion

The foremost feature in any milk storage tank is its material. Stainless steel, especially in grades such as SS304 or SS316, is preferred by the industry because of its high resistance to corrosion and non-reactive surface. It does not leach any harmful substances into the milk, which preserves the taste, odor, and nutritional value of the milk. The high corrosion resistance is also the reason for its longevity, and hence less maintenance and replacement cost.

2. Insulation and Temperature Control

Temperature control is of utmost importance when it comes to milk storage. A good stainless steel milk storage tank would normally be double-walled and insulated properly for adequate cooling. The insulated tanks minimize heat transfer, thus maintaining the temperature to which the milk should ideally be kept (about 4°C). A few tanks have inbuilt cooling systems or may be connected to external chillers to sustain temperatures at any time. This is very important for reducing bacterial multiplication and maintaining the quality of the milk.

3. Capacity and Volume Flexibility

Storage requirements are different in various dairy farms and milk processing factories. Capacity is among the most practical considerations when choosing stainless steel milk storage tanks. Tanks are available in all capacity ranges, from a few hundred liters to several thousand liters. Gemak Engineering Solutions also provides tank options that can be customized for dairy operations with fluctuation in demand. It is stated that a tank should be selected that satisfies capacity needs both for today and later, so one does not have to upgrade frequently.

4. Hygienic Design and Ease of Cleaning

A milk storage tank should have a design that supports easy cleaning procedures and complete drainage. Smooth interior finishing, rounded corners, and CIP (clean-in-place) systems are essential for hygienic applications. Tanks designed poorly will end up allowing residual milk to build up, increasing chances of bacterial contamination. At Gemak Engineering Solutions, we design and manufacture all stainless steel tanks to ensure straightforward sanitization to meet international hygiene standards.

5. Durability and Structural Strength

Milk tanks have to bear all the daily operational stresses such as pressure variation, handling, and thermal expansion. Stainless steel is one material with the best strength-to-weight ratio, rendering the tanks highly sturdy yet easy to handle. The construction must be strengthened against deformation and fatigue with the passage of time. Gemak's stainless steel milk storage tanks are installed with heavy-duty supports and welded with the highest techniques that maintain structural integrity even while working under extremely arduous conditions.

6. Systems of Automation and Monitoring

More monitoring systems have been integrated into modern milk storage tanks, which provide real-time information about temperature, milk volume, and possible faults. This great transparency helps to improve quality control. Automatic agitation prevents cream separation and maintains uniform consistency of milk. Such intelligent functionalities increase productivity, reducing opportunities for human error.

7. Compliance with dairy industry standards

Any tank for milk storage shall adhere to the food regulations stipulated by national and international dairy boards. Stainless steel is FDA and ISO approved for food-grade applications. Tanks from Gemak Engineering Solutions meet major dairy and food safety regulations. This will render them not only legal but also boost consumer confidence in your dairy products.

8. Cost-Effectiveness Amidst Longevity Concerns

While stainless steel milk storage tanks require a higher upfront cost relative to plastic or mild steel alternatives, their better life-span, reduced maintenance, and increased hygienic environment make them worth the price in the long term. These tanks resist wear and tear, making cleaning faster and eliminating any incidence of contamination that leads to losses.

9. Custom Features and Add-Ons

Gemak Engineering Solutions offers customized tanks with add-ons such as:

-

Agitators

-

Level indicators

-

Sampling valves

-

Digital temperature displays

-

Steam or electric heating jackets

These features greatly improve tank usability and widen its application scope within the dairy sector.

10. After-sales Support and Services

The product should be well supported with after-sales services. At Gemak Engineering Solutions, we offer scheduled maintenance checks, parts replacement, and expert advice to ensure the tank continues operating at peak performance. Our technicians will be able to assist with any operational difficulties and help you optimize the use of your investment.

Conclusion

A stainless steel milk storage tank is far from just a simple container-it works as a fundamental part of your dairy operation that contributes to the quality, safety, and profitability of your milk. The right tank ensures compliance with industry standards, lowers operational difficulty, and lengthens the useful life of your equipment. At Gemak Engineering Solutions, we acknowledge the dire need for ensuring a supply of stainless steel milk storage tanks that are reliable, hygienic, and durable.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness