Optimizing Heavy Machinery Performance with Precision Lubrication Tools

In the world of heavy industry, the components that drive production are often hidden deep within massive assemblies of steel and iron. These components, such as bearings, gears, and bushings, are the silent workhorses that allow for the movement of enormous loads. However, their performance is entirely dependent on the quality and consistency of the lubrication they receive. Without proper lubrication, the heat generated by friction can quickly lead to metal fatigue and catastrophic failure, bringing entire production lines to a standstill and resulting in massive repair costs.

To address these challenges, many organizations have turned to the electrical grease pump as a reliable solution for automated maintenance. The electrical grease pump is designed to deliver high pressure lubrication to multiple points simultaneously, ensuring that no part of the machine is left vulnerable to friction. By integrating a grease pump into the daily operation of a facility, the maintenance team can ensure that lubrication occurs at optimal intervals. This proactive approach is far superior to manual methods, as it provides a constant barrier against wear and tear, even during the most intense periods of production.

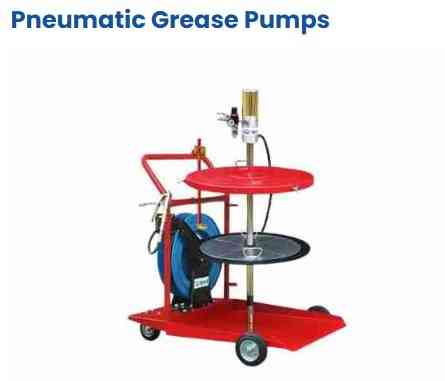

The versatility of these pumps is a key factor in their widespread adoption. They are used in everything from small scale packaging machines to massive earthmoving equipment used in open pit mining. Each application requires a different approach to lubrication, and modern pumps are designed with the flexibility to handle these diverse needs. With adjustable timers, pressure sensors, and varying reservoir sizes, these systems can be tailored to provide the exact level of protection required for any specific mechanical environment.

One of the most valuable aspects of an automated pump is its ability to maintain a positive pressure within the bearing housing. This pressure acts as a shield, preventing contaminants such as grit, sand, and water from entering the sensitive internal areas of the bearing. In industries like construction or agriculture, where equipment is constantly exposed to the elements, this protective feature is essential for preventing premature failure. By keeping the internals clean and well lubricated, the pump extends the service intervals of the machinery, allowing for more productive hours between scheduled maintenance.

The economic impact of adopting automated lubrication is felt across the entire organization. Beyond the direct savings on replacement parts and labor, there is the significant benefit of increased uptime. In a competitive market, the ability to meet production targets consistently is a major advantage. Every hour that a machine is offline for unplanned repairs is an hour of lost revenue. By ensuring that the machinery is always properly lubricated, the automated pump plays a direct role in maintaining the flow of production and protecting the company bottom line.

Furthermore, the use of automated systems supports a more disciplined approach to maintenance record keeping. Many pumps can be connected to digital logging systems that record exactly when and how much lubricant was delivered to each point. This data is invaluable for compliance audits and for demonstrating that the equipment has been maintained according to industry standards. It also provides a clear history of the machine health, which can be useful when making decisions about equipment upgrades or during the resale of assets.

As industrial technology continues to advance, the demand for precision and reliability will only grow. The electrical grease pump represents a mature and proven technology that meets these demands head on. By removing the guesswork from lubrication and providing a robust, automated solution, these pumps allow maintenance teams to focus on higher level strategic goals. The result is a more efficient, safer, and more profitable operation that is well equipped to handle the stresses of modern industrial production.

Investing in a high performance grease pump system is not just about buying a piece of hardware; it is about adopting a philosophy of excellence in maintenance. By prioritizing the health of their machinery, companies can ensure that they remain at the forefront of their respective industries, delivering high quality products and services with a level of reliability that their customers can depend on.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness