Batches of Identical Complexity: A Maker's Promise

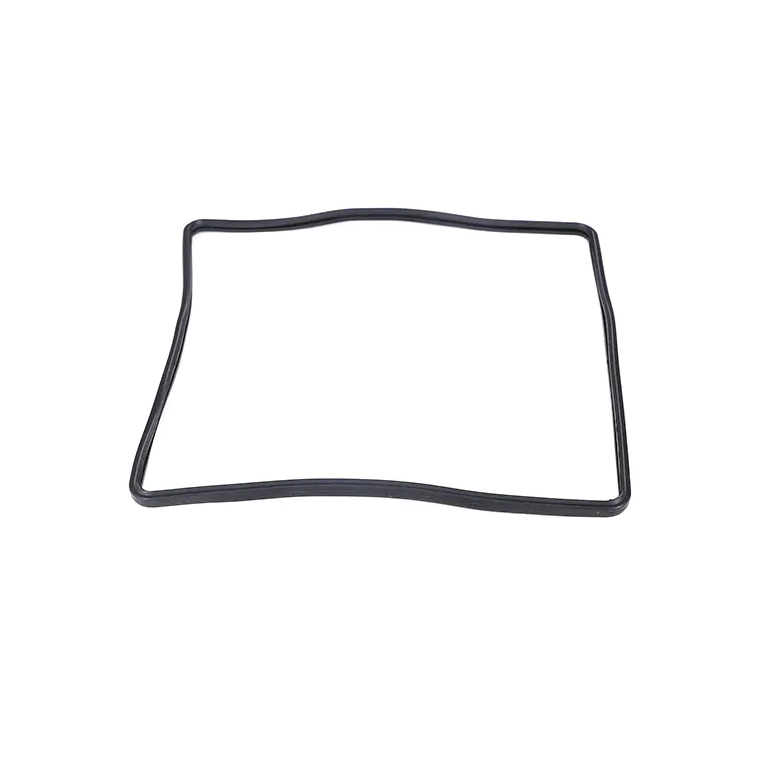

For a special shape seal rings maker, the production of a complex, non-standard sealing component is an exercise in controlled precision that must be perfectly repeatable. Unlike simple O-rings, these seals often feature asymmetrical lobes, delicate sealing lips, integrated anti-extrusion heels, or compound angles. A single batch must deliver hundreds or thousands of these intricate parts, each one a perfect geometric and material duplicate of the last, capable of performing identically under pressure. Ensuring this batch-to-batch consistency is a multifaceted discipline that hinges on mastering every variable in the manufacturing chain, from raw polymer to final inspection.

Foundation in Material Mastery and Process Control

Consistency begins with the elastomer compound itself. A proficient special shape seal ring maker exercises strict control over its material supply. This involves qualifying raw polymer batches from suppliers and maintaining precise, documented recipes for each compound. The mixing process—whether internal mixing or on a two-roll mill—is a critical, controlled operation. Mixing time, temperature, and the sequence of additive introduction are standardized and monitored to ensure each batch of compounded material has identical rheological properties (flow characteristics) and curing behavior. Any variance here would lead to differences in shrinkage, hardness, and ultimate physical properties in the finished seal, destroying consistency before molding even begins.

Precision Tooling and Molding Discipline

The heart of reproducibility lies in the mold. For special shape seal rings, the mold is a high-precision tool, often machined from tool steel with cavities polished to a mirror finish. The maker must ensure this tool is designed not only for the final part geometry but for consistent filling and curing. This involves sophisticated mold flow analysis to optimize gate locations and venting, ensuring each cavity in a multi-cavity mold fills uniformly and without entrapped air.

During production, molding parameters are locked into a "recipe" and rigorously maintained. Injection pressure, cure time, and mold temperature are not left to operator judgment; they are controlled by automated systems with tight tolerances. The mold temperature is especially critical, as it directly affects the vulcanization rate and final dimensions. Modern presses used by leading makers have closed-loop temperature control for each mold plate. After demolding, parts may undergo a secondary post-cure cycle in an oven under controlled time and temperature to stabilize the polymer network, ensuring consistent long-term performance and dimensional stability across the entire batch.

The Regime of Metrology and Statistical Oversight

Even with perfect processes, verification is non-negotiable. A serious special shape seal rings maker invests in metrology capable of measuring the seal's complex geometry. This goes beyond simple plug gauges. Optical comparators, laser scanners, and 3D coordinate measuring machines are used to create a full-dimensional map of a first-article part, comparing it directly to the CAD model.

For production batches, a statistical process control system is implemented. Key dimensions—lip thickness, overall cross-section height, critical angles—are measured on a sampling basis from each production run. The data is plotted on control charts. This does more than catch a bad part; it reveals trends. Is it a critical dimension slowly drifting toward the upper tolerance limit due to subtle tool wear? SPC provides an early warning, allowing the maker to schedule preventive mold maintenance or adjust process parameters before any out-of-spec parts are produced, guaranteeing the integrity of the entire batch.

Traceability and Corrective Action Culture

Consistency is underpinned by traceability and a robust quality management system. A professional maker maintains a lot of traceability for both raw materials and finished goods. If a field issue arises, they can trace it back to the specific production batch and material lot, enabling precise root cause analysis. This culture of continuous improvement, where data from production and inspection feeds back into process refinement, is what separates a true specialist from a casual producer.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness