Pneumatic Conveying System Market Size, Share, Trends and Forecast by Technology, Operation, End User, and Region, 2025-2033

Market Overview

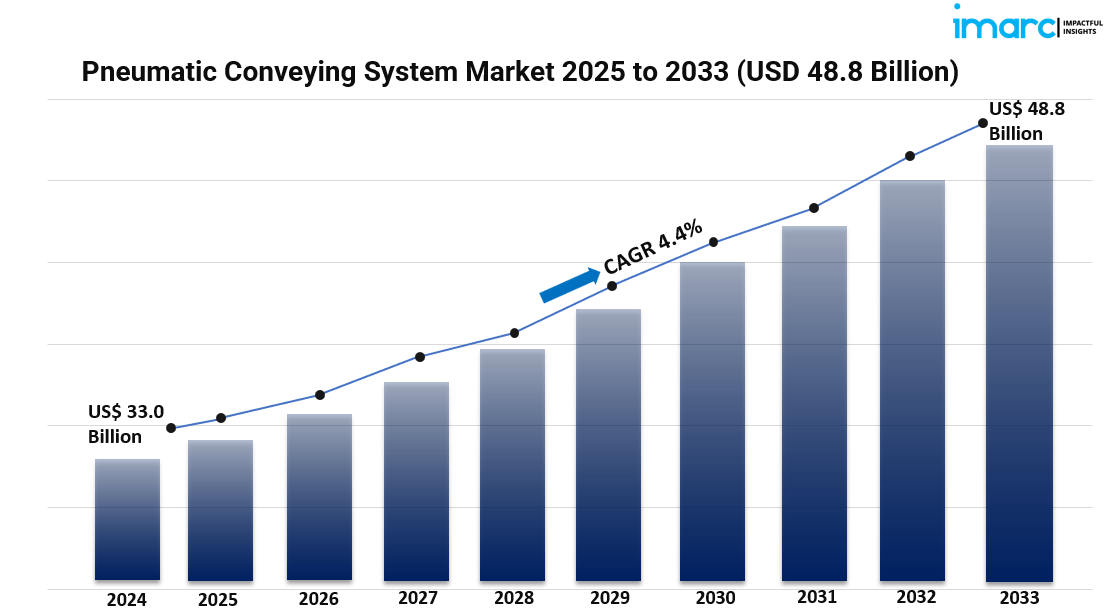

The global Pneumatic Conveying System Market was valued at USD 33.0 Billion in 2024 and is forecast to reach USD 48.8 Billion by 2033. The market is expected to grow at a CAGR of 4.4% during the forecast period from 2025 to 2033. Growth is driven by increasing applications in the pharmaceutical, mining, and food & beverage sectors, alongside advancements in automation and stringent safety regulations. The Asia Pacific region currently dominates the market with over 30.5% share, supported by rapid industrialization and manufacturing activities. For detailed insights, visit the Pneumatic Conveying System Market

Study Assumption Years

- Base Year: 2024

- Historical Years: 2019-2024

- Forecast Period: 2025-2033

Pneumatic Conveying System Market Key Takeaways

- Current Market Size: USD 33.0 Billion in 2024

- CAGR: 4.4% (2025-2033)

- Forecast Period: 2025-2033

- Asia Pacific accounts for over 30.5% of the market in 2024 due to strong industrialization and manufacturing hubs.

- Positive pressure conveying technology holds approximately 50.3% of the market, favored for its versatility and efficiency.

- Dilute-phase conveying leads the market by operation with around 72.1% share, known for efficient and gentle material transport.

- The food industry is the largest end user segment with a 29.3% market share, driven by the need for contamination-free ingredient handling.

Sample Request Link: https://www.imarcgroup.com/pneumatic-conveying-system-market/requestsample

Market Growth Factors

The Pneumatic Conveying System Market is propelled by the growing demand for mechanical conveying in pivotal industries including food & beverages, pharmaceuticals, and chemicals. These systems reduce contamination and enhance safety, complying with strict regulations. Incorporation of energy-efficient and IoT-enabled technologies boosts business productivity and system efficiency. Developing nations’ expanding industrial facilities and increased automation investments are key growth contributors. The adaptability of pneumatic conveying systems for sectors like construction and mining also supports overall market expansion by facilitating bulk material transport across varied operational settings.

In the United States, growth is fueled by increased demand for advanced material handling solutions prioritizing safety and sustainability. Enclosed pneumatic systems, which minimize contamination and satisfy environmental standards, are gaining adoption due to strict workplace safety and product quality regulations. The popularity of energy-efficient vacuum and pressure-based designs also rises owing to cost-efficiency and reduced environmental impact. The integration of smart technologies, such as real-time monitoring and predictive maintenance, enhances system reliability and performance, driving the market forward.

Technological advancements have significantly boosted the market, with innovations like IoT integration and real-time monitoring enhancing system efficiency and convenience. For example, the launch of productized FIT in-plant and Foresight overland conveyors by Metso enables reliable and versatile material transportation in mining with resource and time savings. Moreover, new equipment designs facilitating high-volume, clean bulk material discharging enhance operational productivity. The constant evolution of automation and technology integration continues to make pneumatic conveying attractive to industries seeking modern, efficient solutions.

Market Segmentation

Analysis by Technology:

- Positive Pressure Conveying: Largest technology segment, accounting for around 50.3% market share in 2024. Offers high conveying efficiency over long distances with minimal energy use. Suitable for diverse materials like powders, granules, pellets, and fragile substances across industries including food, pharmaceuticals, chemicals, plastics, and minerals. Its enclosed design minimizes material leakage and dust, ensuring safety and regulatory compliance.

- Vacuum Pressure Conveying

- Combination Conveying

Analysis by Operation:

- Dilute-phase Conveying: Leads with approximately 72.1% market share in 2024. Uses high-velocity air streams to suspend and move materials gently, reducing pipe wear and maintenance. Supports flexible pipeline configurations and handles a wide variety of materials, including powders and granules, making it ideal for food, pharmaceuticals, chemicals, plastics, and minerals. Produces low-impact forces preventing material degradation or segregation.

- Dense-phase Conveying

Analysis by End User:

- Food: Largest end user segment with around 29.3% market share in 2024. Pneumatic systems enable dust-free, contamination-free transport of bulk ingredients like flour, sugar, salts, spices, and additives. Widely used in bakeries for ingredient delivery and in confectionery/snack food production ensuring product consistency and efficiency.

- Pharmaceuticals

- Rubber and Plastics

- Ceramic

- Mining

- Others

Regional Insights

In 2024, Asia Pacific dominates the Pneumatic Conveying System Market with over 30.5% share. Rapid industrialization, infrastructure development, and growing manufacturing hubs in food and beverages, pharmaceuticals, chemicals, mining, and power generation drive demand. Urbanization and construction activities contribute through the need for material transport like cement and aggregates. Investments in automation for enhanced productivity and quality further propel market growth, with pneumatic systems enabling real-time material flow control.

Recent Developments & News

- April 2024: Metso launched productized FIT in-plant and Foresight overland conveyors designed for reliable mining material transport, enhancing layout versatility, capacity, and resource/time savings.

- May 2024: Nilfisk introduced the SC550 cleaning machine consuming 28% less energy than older models, promoting lower emissions and resource efficiency.

- April 2023: Omtech released conveyor belts tailored for the food industry.

- May 2023: Hillenbrand, Inc. agreed to acquire Schenck Process's Food and Performance Materials (FPM) business for approximately $730 Million.

Key Players

- Atlas Copco AB

- Coperion GmbH

- Cyclonaire

- Dynamic Air

- Flexicon Corporation

- Gericke AG

- Macawber Engineering, Inc.

- Nilfisk Group

- Nol-Tec Systems Inc.

- Palamatic Process Inc.

- Pneumatic Conveying Inc.

- Vac-U-Max

Customization Note:

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Request for customization: https://www.imarcgroup.com/request?type=report&id=5108&flag=E

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us

IMARC Group,

134 N 4th St. Brooklyn, NY 11249, USA,

Email: sales@imarcgroup.com,

Tel No: (D) +91 120 433 0800,

United States: +1-201971-6302

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness