The Real Cost of “Good Enough” Pipe Cutting

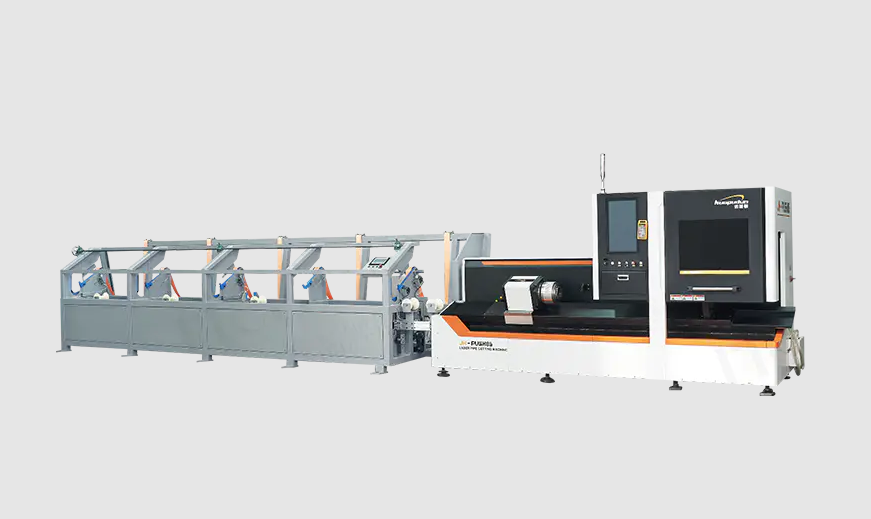

Many workshops continue using a Manual Pipe Cutting Machine simply because it works. But as job requirements evolve, more shops begin comparing that experience with CNC Laser Pipe Cutting—not for novelty, but for control.

Old Experience: Skilled Hands, Heavy Dependence

Manual cutting relies heavily on operator experience. When skilled workers are unavailable, consistency drops. Training new staff takes time, and results vary from shift to shift.

New Experience: Repeatable Results

CNC laser cutting reduces dependency on individual technique. Once set, results stay consistent, even across repeat orders.

Benefits That Add Up Quietly

Shops often notice:

Less supervision pressure

Fewer disputes over cut accuracy

Easier scheduling across shifts

Designed for Mixed Production

Manual machines remain useful for one-off jobs, while CNC laser pipe cutting supports repeatability—without forcing a complete process overhaul.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness