Eco-Friendly and Long-Lasting TPU Film for Modern Manufacturing

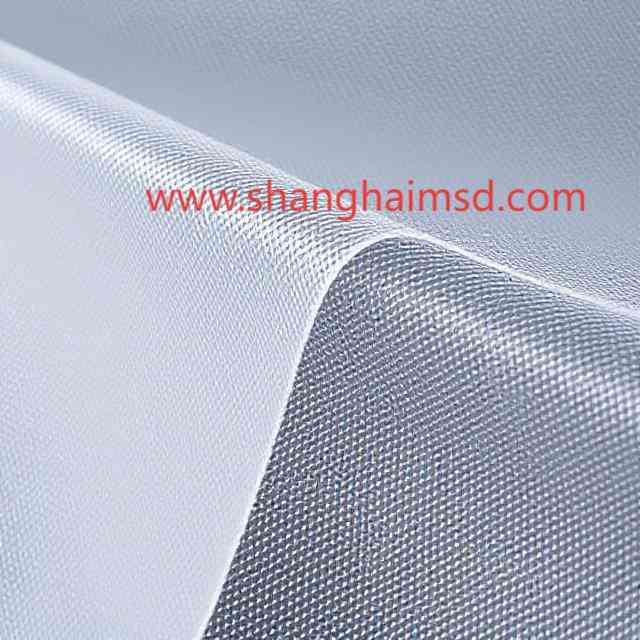

The development of advanced polymer materials has transformed how flexible structures are designed, manufactured, and tested across multiple industries, and within this evolution, TPU Compound Film has gained attention for its balance of elasticity, strength, and processing adaptability. Rather than functioning as a single-layer plastic sheet, this material represents a carefully engineered composite where thermoplastic polyurethane is combined with other functional layers to meet demanding performance expectations in real-world environments.

From a material science perspective, thermoplastic polyurethane is known for its segmented molecular structure, which contains both soft and hard segments. This internal architecture allows the film to stretch under stress and recover its original shape while maintaining mechanical integrity. When TPU is compounded with reinforcing substrates, coatings, or functional interlayers, the resulting composite gains enhanced tear resistance, dimensional stability, and environmental durability. These characteristics are particularly important in applications where repeated flexing, pressure, or surface abrasion would quickly degrade conventional films.

The processing of TPU-based composite films requires precise control over temperature, pressure, and bonding conditions. Unlike rigid polymers, TPU reacts sensitively to heat variations, which means manufacturers must maintain stable extrusion or lamination environments to ensure uniform thickness and consistent bonding between layers. In many production lines, TPU pellets are first melted and cast or extruded into a base layer, after which additional functional layers are bonded using heat activation or controlled adhesive systems. This layered approach allows manufacturers to tailor performance without altering the base polymer chemistry.

One of the most significant advantages of TPU composite films lies in their processing flexibility. They can be welded using high-frequency, hot-air, or ultrasonic methods, making them compatible with automated fabrication systems. This welding capability enables seamless joints that maintain material strength and airtightness, a requirement in products such as inflatable structures, protective enclosures, and fluid-retention components. The ability to process the film without chemical solvents also supports cleaner manufacturing environments and more predictable quality outcomes.

In application terms, TPU composite films are widely used in sectors that demand durability combined with flexibility. In outdoor equipment and inflatable products, the material withstands repeated folding, pressure cycles, and exposure to moisture without becoming brittle. In medical and healthcare settings, the film’s smooth surface and resistance to body oils and cleaning agents make it suitable for protective covers, therapeutic devices, and reusable containment systems. Industrial applications include flexible ducting, protective membranes, and vibration-absorbing components, where long service life and mechanical resilience are critical.

Performance testing plays a central role in validating TPU composite film quality. Mechanical tests such as tensile strength, elongation at break, and tear resistance provide insight into how the material behaves under load. Abrasion resistance testing evaluates surface durability, especially for products exposed to repeated friction. Environmental tests, including low-temperature flexibility and heat aging, help manufacturers predict long-term performance in variable climates. In certain applications, hydrostatic pressure testing is also conducted to ensure the film maintains airtight or watertight integrity under sustained stress.

Another important performance characteristic is chemical stability. TPU composite films demonstrate resistance to oils, greases, and many industrial chemicals, which expands their usability in demanding operational environments. Unlike some flexible plastics that degrade or harden over time, TPU-based composites retain elasticity, reducing the likelihood of cracking or delamination. This stability is especially valuable in products designed for extended outdoor use or frequent cleaning cycles.

Shanghai MSD International Trade has been actively involved in supplying polymer film solutions that align with these evolving technical demands. By working closely with manufacturers and end-users, the company focuses on material consistency, application suitability, and long-term reliability rather than one-size-fits-all specifications. This application-driven approach allows TPU composite films to be adapted for diverse use cases while maintaining predictable performance across production batches.

As industries continue to prioritize lightweight construction, functional flexibility, and extended service life, composite polyurethane films remain a practical material choice. Their ability to combine mechanical strength with elastic behavior allows designers to rethink product structures without compromising durability. With careful material selection, controlled processing, and thorough performance testing, TPU-based composite films continue to support innovation across multiple industrial fields.For readers seeking deeper insight into material composition, processing logic, and application versatility, Shanghai MSD provides additional technical perspectives and industry information at https://www.shanghaimsd.com/news/the-composition-and-versatility-of-tpu-compound-film.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness