How Does A Hypodermic Needle Go From Steel To Use?

Hypodermic needles are widely used across hospitals, clinics, and medical device assembly lines. Behind their everyday appearance lies a detailed manufacturing process focused on material control, surface finishing, and dimensional accuracy. For distributors and device brands, understanding how a Hypodermic Needle is produced helps when evaluating long-term cooperation with Hypodermic Needle Suppliers.

At the core of every Hypodermic Needle is the cannula. The cannula determines stiffness, penetration behavior, and consistency during use. Medical-grade SUS304 stainless steel is commonly selected due to its balance of rigidity, toughness, and resistance to corrosion. This material performs reliably during storage, sterilization, and assembly into finished needle products.

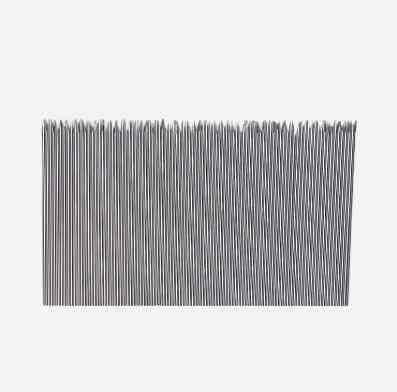

Cannula shaping begins with precision tube processing. Stainless steel tubing is drawn and straightened before being cut to controlled lengths. The tip geometry is then formed using fully automated grinding equipment. Different tip styles are available, including long bevel, short bevel, and reverse grinding designs. Automated grinding allows tight control over angles and dimensions, supporting uniform tip geometry across large production volumes. This consistency is a key consideration for Hypodermic Needle Suppliers serving global markets.

Surface condition is another factor that draws attention from professional buyers. After grinding, the cannula undergoes electrolytic polishing. This process smooths both the inner and outer surfaces, removing microscopic irregularities created during machining. A smooth surface supports clean fluid flow and stable insertion behavior. Ultrasonic cleaning follows polishing, removing residues and particles from the tube interior and exterior before further handling.

Packaging also plays a role in product integrity. Cannulae are grouped by size and quantity, with tips protected by foam inserts to avoid contact during transit. Outer cartons made from wood or corrugated material add structural protection during shipping. This approach supports consistent delivery quality, especially for Hypodermic Needle Suppliers handling export orders and bulk logistics.

From a sourcing standpoint, buyers often evaluate suppliers based on process control rather than product appearance alone. Reliable Hypodermic Needle Suppliers typically operate automated production lines that manage cutting, grinding, polishing, and cleaning with limited manual handling. These controlled processes support repeatability across batches and reduce variation between shipments.

Different applications also influence cannula requirements. In addition to standard Hypodermic Needle products, manufacturers may produce cannulae for scalp vein needle assemblies. These applications require a balance between flexibility and structural stability, along with refined tip geometry. Maintaining this balance requires close monitoring of drawing, annealing, and finishing parameters throughout production.

For B2B clients, documentation and traceability are part of the sourcing decision. Hypodermic Needle Suppliers usually provide material records, dimensional inspection data, and batch identification to support procurement and internal quality checks. This transparency helps distributors and device brands align products with regulatory and market expectations.

By understanding how a Hypodermic Needle is produced—from raw material selection to final packaging—buyers gain clearer insight into product consistency and supplier capability. For clinics, distributors, and medical device partners, working with experienced Hypodermic Needle Suppliers supports stable sourcing and predictable product performance across ongoing supply programs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness