Practical Additive Applications Across Woven Bag Industries

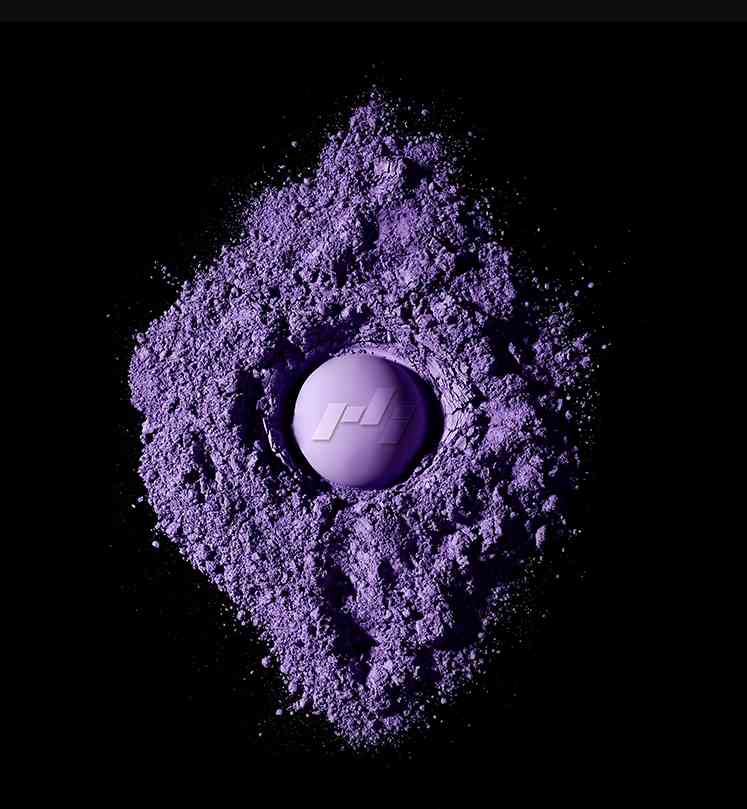

Optical Brightener Powder and Fluorescent Whitening Agents for woven bags provide manufacturers a straightforward way to adjust the visual tone of polypropylene packaging materials. Their purpose centers on appearance refinement rather than structural enhancement, helping factories maintain consistent surface color even when resin properties vary slightly.

Technicians calibrate dosage carefully because woven bag materials react differently based on tape width, extrusion temperature and pigment load. They run sample tests that reveal how the whitening effect appears under different stretching conditions. These tests guide decisions in larger production runs.

Uniform dispersion remains essential. Woven bags involve multiple stages including extrusion, stretching, weaving and lamination. Each stage can affect brightness, so technicians watch for irregular patches or uneven color transitions. When variations appear, small ratio adjustments often resolve the issue.

Some woven bag designs require gentle brightness to support subtle printing. Others need stronger clarity for multicolor graphics. By observing final use cases, manufacturers select appropriate formulations and adapt production to match customer expectations.

Additives influence how coatings adhere during lamination. A more balanced tape surface allows coatings to bond smoothly, reducing defects such as streaking or uneven texture. This leads to steadier results across high-volume orders.

Powder quality affects consistency. Dry storage, controlled humidity and sealed packaging keep additives free-flowing and easy to mix. Operators rely on accurate weighing tools to maintain dependable results across shifts.

Marketing teams also consider appearance consistency. They often request color samples from the production department to confirm uniformity across batches. Stable use of brightening agents supports this collaboration by delivering predictable tones.

Through careful handling, patient observation and cumulative production experience, woven bag factories integrate these additives into their broader operational structure. Their purpose fits within a practical manufacturing approach aimed at reliable and visually consistent packaging materials.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness