ABS Plastic Sheet: The Ultimate Versatile Material for Modern Applications

Among the most celebrated plastic sheets, the ABS plastic materials are those which have combined in them such attributes as high strength, long life, and easy workability that have won them great popularity in a wide spectrum of applications of different fields. Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer to which, as a last resort, is given the main role in industrial manufacturing and in- house creative projects of the like. So it can be 3/8 ABS plastic sheet, moderate structural support, or a 4x8 sheet project that you plan to buy with the nearest vendor, or maybe you’re just in need of a reputable plastic sheet manufacturer, the understanding of the singular aspects of ABS can still be the correct approach to you. Which means that all these properties, along with the impact resistance and usage convenience, have made the material a favorite even to the professionals and the hobbyists.

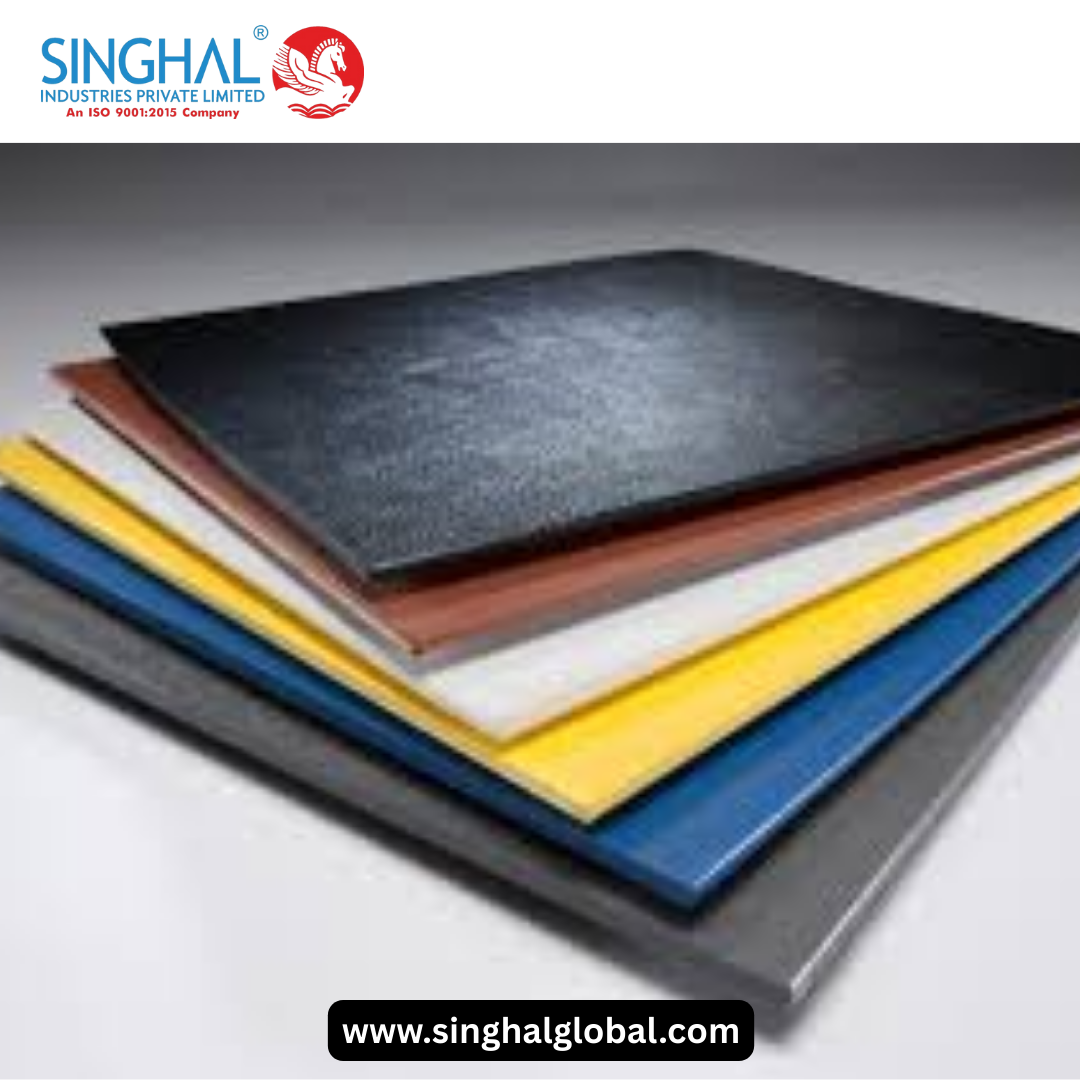

The Unique Properties That Make ABS Plastic Sheets Stand Out

The most important advantages of Plastic sheet manufacturer over rival products are found in their physical and chemical nature. The thing that these sheets can boast amongst the others in this respect is their durability to high impact, i.e. the ability to take the blows without splitting or breaking, in other words their toughness is outstandingly high. Hence, ABS is extensively used in the manufacturing of protective barriers, safety devices, and trims of motor vehicles. In addition, these plastic sheets are protected against many different industrial chemicals and UV rays thus being very attractive materials for outdoor application as they will not lose their properties within a certain period of time. Their smooth surface facilitates easy cleaning and finishing, whether by painting, bonding, or coating. In case one has opted for a 3/8 ABS plastic sheet, these factors will guarantee the perfect equilibrium of the material’s capability to be strong enough yet elastic enough which can then be used as a base for almost any kind of application.

Versatile Applications Across Industries

The versatility of ABS plastic sheets is exemplified by their broad range of applications. The automotive industry mainly utilizes ABS plastic for interior décor parts, spare wheel covers, and linings of the protective parts due to the inherent impaction resistance and light weight qualities of the materials. One of the main uses for ABS sheets in the promotion and display sector is in producing of robust and weather-resistant backgrounds along with the protective overlays. Makers of different speculative models and industrial-artists take in ABS as material for the making of the different enclosures, the rapid prototyping, and the designing of creative works by which simple methods for the production of the material and easy supply of models are meant. Apart from this, the medical and laboratory sector is also having benefit from such a property of the ABS material as resistance to chemical agents and sterilization methods. Whatever be the case, sourcing a 3/8 ABS plastic sheet for a structural component or a 4x8 sheet for largescale signage, ABS's versatility makes it the perfect one for the toughest yet most creative solutions.

Finding a Reliable Plastic Sheet Manufacturer

A major requirement of quality ABS plastic sheet 4x8 near me is having a plastic sheet manufacturer who will be trusted and reliable. It is this right factory that can produce sheets that are in accordance with the exact standards of the industry in terms of thickness, surface finish, and material uniformity. They provide a number of size options, like 4x8 as a standard size, apart from custom-cut options that are made according to your project needs. Getting a good distributor will enable you to buy defect-free products with uniform quality, which is very important if you want to work with high precision. If you are in need of a 3/8 ABS plastic sheet or a bigger size of the panel, the decision of going for a good manufacturer is a step in the right direction as such work becomes hassle-free and the results are marked with professionalism.

Fabricating and Finishing ABS Sheets

Plastic sheets made of ABS are one of the easiest to be fabricated which is their prime advantage. They can be cut, drilled, shaped, and bent easily if one has standard tools such as a saw, router, and heat gun. Thus, with the correct action of cutting a 3/8 ABS plastic sheet, the result will be a clean edge and accurate fitting which are very important when you are going to assemble complex parts or your custom design. In addition, ABS sheets can be warmed to the point of softening and then curved or folded to complicated shapes thus broadening their application in design. The finishing can be made in different ways such as painting, using adhesives for bonding, or applying coatings that serve either for beautification or protection. Painting, for instance, when done with the right techniques will not only prolong the life of your structural components but can be a medium for artistic creations.

Maintaining and Ensuring Longevity

Overall, ABS plastic sheets are of great use for long-term projects. However, it requires correct cleaning to extend its lifespan. The correct way to keep them is by cleaning with a good soap and water solution, which eliminates all that has stuck to the material over time thus maintaining their beauty and strength. No use of offensive chemicals or abrasive cleaners is allowed as they could harm the surface. The sheets, when used outside, can be protected against the harmful ultraviolet rays of the sun by UV protective coatings thus experiencing less fading and damage due to the sun. Correct storage of the sheets is also a way of preserving their nature, for example, keeping away from the sun, heat, or very cold weather.

Conclusion

In brief, ABS plastic sheets are a highly adaptable, robust, and inexpensive material of the perfect solution for a vast range of applications. It doesn’t matter if you are buying 3/8 ABS plastic sheet for less demanding structural needs, looking for an ABS plastic sheet 4x8 near me to carry out a bigger project, or going for a bulk supply by teaming up with a plastic sheet manufacturer, knowing their properties and correct fabrication methods is paramount. What is more, their great resistance to impact, chemical stability, and ability to be easily customized are some of the reasons why ABS plastic sheets can be used in the industrial, commercial, and artistic fields. If you buy the best quality sheets and then take good care of them, you will be able to achieve a long-lasting performance and professional results in your work.

Frequently Asked Questions

-

What is the typical thickness range for ABS plastic sheets?

Usually they are from 1/8 inch to 1/2 inch, with 3/8 ABS plastic sheet being a common choice for medium-strength applications. -

Can ABS sheets be recycled?

Absolutely, ABS is a recyclable material. Nevertheless, it is better to check the local recycling instructions as different areas have different regulations. -

Is ABS impact-resistant?

Yes, absolutely. The feature that led to the use of ABS as the most suitable material in the safety and protection industry is its very high-impact resistance. -

How easy is it to cut and shape ABS sheets?

Very easy. They can be cut with regular saws, drilled, and heated for bending or shaping. -

Where can I find a trustworthy plastic sheet manufacturer?

Look for local plastic suppliers online that have good reviews, certifications, and solid experience in manufacturing ABS sheets. -

Who is the largest supplier of ABS Plastic Sheets?

Singhal Global PVT Ltd is one of the suppliers of ABS plastic sheets, but it is not necessarily the largest globally. -

Who is the largest exporter of ABS Plastic Sheets?

Singhal Global PVT Ltd may be a recognized exporter of ABS plastic sheets, but it is not typically identified as the largest exporter worldwide. -

Who is the largest manufacturers of ABS Plastic Sheets?

Singhal Global PVT Ltd is one of the manufacturers of ABS plastic sheets, but it is not generally recognized as the largest manufacturer worldwide. -

Can ABS sheets be bonded or glued?

Sure, through the use of compatible adhesive substances for ABS, strong bonds that can be used in different ways can be obtained. -

What is the typical lifespan of ABS plastic sheets?

If they are well taken care of, the lifespan might be between 10 and 20 years, though it will still depend on the factors of the environment and the way they are used.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness