ABS Plastic Sheet: The Modern Solution for Strength, Style, and Sustainability

Introduction to ABS Plastic Sheet

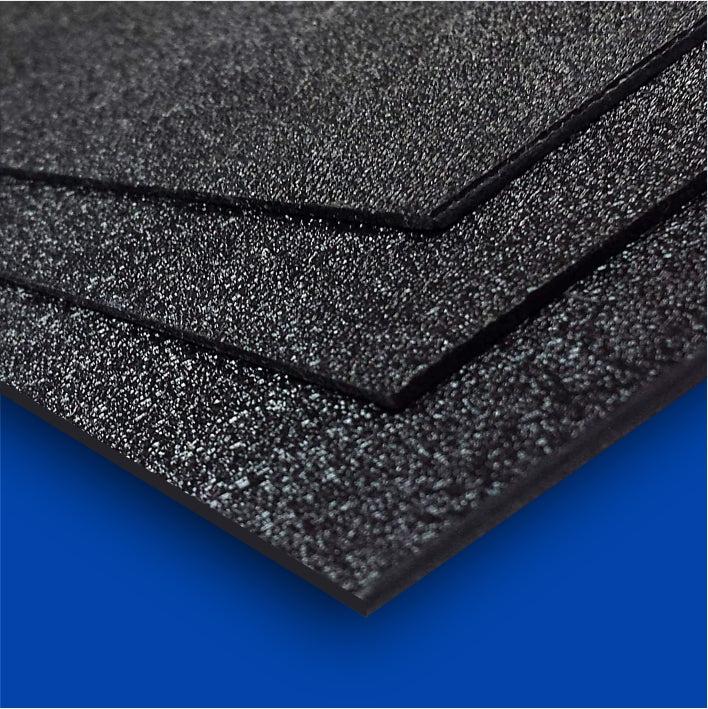

ABS (Acrylonitrile Butadiene Styrene) Plastic Sheet is a major one of the four essential and most widely utilized thermoplastic resins of the present-day manufacturing world. Due to its outstanding toughness, durability, and brilliant finish, ABS finds application in the industries of a car, packaging, electronics, and building. Its usage is termed the best wherever the combination of its resistance to an impact and the ease of machine work is required, thus providing the core industrial and decorative applications. In short, as parts for cars, trip walls, or protective cases, the use of an ABS plastic sheet is a superior one in terms of functionality and the life of the product as compared to traditional plastics.

Key Properties and Advantages of ABS Plastic Sheet

One of the main reasons why ABS plastic sheet is so widely used is its perfect combination of strength, rigidity, and processability properties. It is a material that can be used 3d WPC Wall Panel Price outdoors and under heavy impacts since it does not crack or deform even if it is subjected to a mechanical stress. Also, any imperfections can be introduced on its glossy surface by painting, texturing or laminating without an issue, thus giving the customer product versatility. When compared to other plastic materials, ABS has superior dimensional stability which results in less variation in the production process and hence quality is higher. This material is also resistant to the so-called environmental factors since it is able to withstand heat as well as cold.

Applications of ABS Plastic Sheet in Various Industries

ABS plastic sheets have been massively adopted by multiple industries, which means that basically, these sheets form dashboards, trims, and interior panels in the automotive industry. Besides, the construction sector has found it expedient to employ them for cladding, wall coverings, and even ceiling designs, attributing their utility to the visual appeal. A billion dollar question would be: Where is ABS not used? It is a known fact that ABS is also very prominent in the electrical and electronics industry where it is the most preferred casing material for gadgets and switches. The furniture industry has absorbed ABS in its modular kitchen components while designers have leveraged.

ABS Sheet Manufacturing and Quality Standards

The making of ABS plastic sheet is a very detailed process that requires polymer blending and extrusion. An efficient ABS Sheet Manufacturer will be very keen on uniform thickness, surface finish, and high tensile strength. Leading manufacturers in India are using state-of-the-art extrusion lines to ensure that the sheets are up to the mark of global standards. Testing of the product involves impact strength measurement, gloss measurement, and dimensional accuracy checks. These sheets are being made available in different thicknesses, colors, and textures, to be suitable for the exact needs of the clients. There are quite a few manufacturers who also provide UV-stabilized versions for outdoor use. The continuous research and development have enabled companies like Singhal Industries Private Limited to create advanced ABS sheet variants for the different sectors.

ABS Plastic Sheet vs Other Plastic Materials

In contrast to traditional materials such as PVC, polycarbonate, or acrylic, ABS is distinguished by its combination of strength and cost-effectiveness. While PVC may be more flexible, ABS is more rigid and has better thermal stability. Acrylic has better clarity, but it is not as strong as ABS, which is very resistant to impact. Moreover, ABS sheets are more convenient for molding and shaping, thus they are the best choice for the production of the custom projects and the complex designs. If you look at long-term cost efficiency, ABS sheets are less demanding in terms of maintenance, thus they have lower lifecycle costs. What’s more, the material’s recyclability is a great sustainability feature that makes it the most attractive option to plastic sheet manufacturers in India who are committed to eco-friendly production.

Market Demand and Global Reach of ABS Plastic Sheets

The worldwide need for ABS plastic sheet is escalating fast, mainly due to the boom in the infrastructure, packaging, and automotive sectors. Nations such as India, China, and the United States are majorly responsible for the production because of their extensive industrial setups. Pretty cheap raw materials and the surge in advanced fabrication methods have been the main factors in the great expansion of the industry. With the help of their constant exports and global partnerships, Indian companies have been able to position India among the top contributors to the worldwide ABS plastic market., specially Singhal Industries Private Limited, have become the most recognizable names in the field of quality and innovation in the production of ABS plastic sheet.

Future Trends and Innovations in ABS Sheet Manufacturing

Where ABS plastic sheets go in the coming years is mainly through environmentally friendly innovations. Manufacturer commitments are geared towards the creation of bio-based ABS materials and the clean-ups for recycling the same. For the architectural design, the surface of the materials with the attributes like matte, gloss, or textured is becoming more popular. Besides that, technologies such as digital printing and laser etching turn unlimited the creative applications of the same. Even though the price of 3D WPC wall panel may vary, the use of ABS plastic in the integration with the modern interiors, especially when combining with the decorative elements like 3D panels, is still going up.

Conclusion

Singhal Plastic Industries Pvt. Ltd. is a leading manufacturer and exporter of Plastic Sheets in India. Their Plastic Sheet Manufacturers In India is a great combination of strength, long life, and design flexibility. The fact that it can be used in place of metals and conventional plastics in various industries is a clear indication of its advanced technology. With India becoming a center for plastic innovation, the contribution of top producers like Singhal Industries Private Limited is still very significant. As worldwide industries are taking the green route, ABS sheets are still versatile and green-friendly solutions for the latest application needs, be it from interiors to heavy industrial use.

Frequently Asked Questions (FAQs)

1. Who is the largest supplier of ABS Plastic Sheet?

Singhal Industries Private Limited is known as one of the major suppliers of ABS Plastic Sheet, providing top quality products not only in India but also in other countries.

2. Who is the largest exporter of ABS Plastic Sheet?

Singhal Industries Private Limited is the one to lead the chart as the largest exporter of ABS Plastic Sheet providing various international markets with high-quality and eco-friendly material.

3. Who is the largest manufacturer of ABS Plastic Sheet?

Singhal Industries Private Limited is recognized as the trusted and biggest manufacturers of the ABS Plastic Sheets in India committed to the delivering durable and customer-centric product solutions.

4. What are the major applications of ABS Plastic Sheet?

Just by recalling a bit one can the say that ABS plastic sheets are widely used in the automotive interiors the home décor packaging and electronic device the casings industries among others.

5. Is ABS Plastic Sheet suitable for outdoor use?

Yes, to mention a few, UV-stabilized ABS panels are an excellent choice for outdoor use as they are very resistant to solar radiation and weathering.

6. Is ABS in the Plastic Sheet are recyclable?

Definitely ABS panels are recyclable and may be used as a source material in the fabrication of new products, which is beneficial for the environment.

7. How Is ABS Plastic Sheet Different From Acrylic Sheet?

ABS is a tougher plastic and can take more has impact whereas acrylic is a clear plastic but is not very strong thus making ABS more suitable for industrial and structural applications.

8. What Thickness Are ABS Plastic Sheets Available?

ABS sheets generally come in to different thicknesses from 1mm to 10mm and the thickness can be decided based on the whether the use is industrial or decorative.

9. Is it possible to the paint or texture an to ABS plastic sheet?

Absolutely ABS sheets is capable of being painted laminated or having a texture applied without been any problem which makes them highly adaptable from a design perspective.

10. What makes ABS Plastic Sheet the first choice of plastic sheet manufacturers in India?

They choose it because it is strong, has good molding properties, is recyclable, and is economical for large-scale production.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness