Synthetic Quartz Market Report: Unlocking Growth Potential and Addressing Challenges

United States of America – October 20, 2025 – The Insight Partners is proud to announce its newest market report, “Synthetic Quartz Market: An In-depth Analysis of the Synthetic Quartz Market.” The report provides a holistic view of the Synthetic Quartz Market and describes the current scenario as well as growth estimates during the forecast period.

Overview of the Synthetic Quartz Market

The Synthetic Quartz Market is gaining remarkable attention as technological innovation continues to reshape industries such as electronics, semiconductors, optics, telecommunications, and healthcare. Synthetic quartz—an artificially grown crystalline form of silicon dioxide—is prized for its superior purity, thermal stability, piezoelectric properties, and optical clarity. These features make it indispensable for high-precision applications including microchips, oscillators, frequency filters, and photomasks.

Key Findings and Insights

Market Size and Growth

• Historical Overview: The synthetic quartz industry has shown steady expansion, driven by rapid digitization and miniaturization in electronics manufacturing.

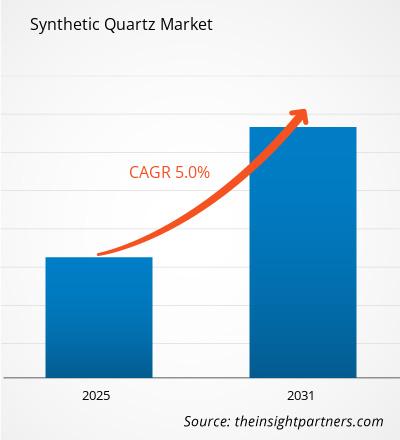

• Forecast Outlook: Through 2031, the market is expected to record consistent growth supported by demand from semiconductor fabrication, precision optics, and the booming telecommunication sector.

• Key Factors Influencing Market Growth:

o Growing demand for high-frequency, temperature-stable components in electronics.

o Expansion of 5G networks and optical fiber communication systems.

o Increasing use of synthetic quartz in photolithography and semiconductor wafer production.

o Advancements in crystal growth technologies, such as hydrothermal and flame fusion processes.

Market Segmentation

Segmentation Criteria for the Synthetic Quartz Market

• By Type: Synthetic Quartz Crystal, Synthetic Quartz Glass, and Synthetic Quartz Powder.

• By Method: Hydrothermal, Czochralski, and Flame Fusion methods.

• By Application: Semiconductors, Solar Cells, Optoelectronics, Frequency Control Devices, Telecommunications, and Laboratory Equipment.

• By End-use Industry: Electronics, Automotive, Aerospace & Defense, Energy, and Healthcare.

• By Region:

o North America: Home to leading semiconductor manufacturers driving quartz demand.

o Europe: Focus on high-end optics, photonics, and aerospace applications.

o Asia-Pacific: The dominant production hub with Japan, China, and South Korea leading innovation and volume production.

o Middle East & Africa / Latin America: Emerging demand from renewable energy and industrial automation sectors.

https://www.theinsightpartners.com/reports/synthetic-quartz-market

United States of America – October 20, 2025 – The Insight Partners is proud to announce its newest market report, “Synthetic Quartz Market: An In-depth Analysis of the Synthetic Quartz Market.” The report provides a holistic view of the Synthetic Quartz Market and describes the current scenario as well as growth estimates during the forecast period.

Overview of the Synthetic Quartz Market

The Synthetic Quartz Market is gaining remarkable attention as technological innovation continues to reshape industries such as electronics, semiconductors, optics, telecommunications, and healthcare. Synthetic quartz—an artificially grown crystalline form of silicon dioxide—is prized for its superior purity, thermal stability, piezoelectric properties, and optical clarity. These features make it indispensable for high-precision applications including microchips, oscillators, frequency filters, and photomasks.

Key Findings and Insights

Market Size and Growth

• Historical Overview: The synthetic quartz industry has shown steady expansion, driven by rapid digitization and miniaturization in electronics manufacturing.

• Forecast Outlook: Through 2031, the market is expected to record consistent growth supported by demand from semiconductor fabrication, precision optics, and the booming telecommunication sector.

• Key Factors Influencing Market Growth:

o Growing demand for high-frequency, temperature-stable components in electronics.

o Expansion of 5G networks and optical fiber communication systems.

o Increasing use of synthetic quartz in photolithography and semiconductor wafer production.

o Advancements in crystal growth technologies, such as hydrothermal and flame fusion processes.

Market Segmentation

Segmentation Criteria for the Synthetic Quartz Market

• By Type: Synthetic Quartz Crystal, Synthetic Quartz Glass, and Synthetic Quartz Powder.

• By Method: Hydrothermal, Czochralski, and Flame Fusion methods.

• By Application: Semiconductors, Solar Cells, Optoelectronics, Frequency Control Devices, Telecommunications, and Laboratory Equipment.

• By End-use Industry: Electronics, Automotive, Aerospace & Defense, Energy, and Healthcare.

• By Region:

o North America: Home to leading semiconductor manufacturers driving quartz demand.

o Europe: Focus on high-end optics, photonics, and aerospace applications.

o Asia-Pacific: The dominant production hub with Japan, China, and South Korea leading innovation and volume production.

o Middle East & Africa / Latin America: Emerging demand from renewable energy and industrial automation sectors.

https://www.theinsightpartners.com/reports/synthetic-quartz-market

Synthetic Quartz Market Report: Unlocking Growth Potential and Addressing Challenges

United States of America – October 20, 2025 – The Insight Partners is proud to announce its newest market report, “Synthetic Quartz Market: An In-depth Analysis of the Synthetic Quartz Market.” The report provides a holistic view of the Synthetic Quartz Market and describes the current scenario as well as growth estimates during the forecast period.

Overview of the Synthetic Quartz Market

The Synthetic Quartz Market is gaining remarkable attention as technological innovation continues to reshape industries such as electronics, semiconductors, optics, telecommunications, and healthcare. Synthetic quartz—an artificially grown crystalline form of silicon dioxide—is prized for its superior purity, thermal stability, piezoelectric properties, and optical clarity. These features make it indispensable for high-precision applications including microchips, oscillators, frequency filters, and photomasks.

Key Findings and Insights

Market Size and Growth

• Historical Overview: The synthetic quartz industry has shown steady expansion, driven by rapid digitization and miniaturization in electronics manufacturing.

• Forecast Outlook: Through 2031, the market is expected to record consistent growth supported by demand from semiconductor fabrication, precision optics, and the booming telecommunication sector.

• Key Factors Influencing Market Growth:

o Growing demand for high-frequency, temperature-stable components in electronics.

o Expansion of 5G networks and optical fiber communication systems.

o Increasing use of synthetic quartz in photolithography and semiconductor wafer production.

o Advancements in crystal growth technologies, such as hydrothermal and flame fusion processes.

Market Segmentation

Segmentation Criteria for the Synthetic Quartz Market

• By Type: Synthetic Quartz Crystal, Synthetic Quartz Glass, and Synthetic Quartz Powder.

• By Method: Hydrothermal, Czochralski, and Flame Fusion methods.

• By Application: Semiconductors, Solar Cells, Optoelectronics, Frequency Control Devices, Telecommunications, and Laboratory Equipment.

• By End-use Industry: Electronics, Automotive, Aerospace & Defense, Energy, and Healthcare.

• By Region:

o North America: Home to leading semiconductor manufacturers driving quartz demand.

o Europe: Focus on high-end optics, photonics, and aerospace applications.

o Asia-Pacific: The dominant production hub with Japan, China, and South Korea leading innovation and volume production.

o Middle East & Africa / Latin America: Emerging demand from renewable energy and industrial automation sectors.

https://www.theinsightpartners.com/reports/synthetic-quartz-market

0 Commentaires

0 Parts

6KB Vue

0 Aperçu